|

| | Time,timing,time area ? |  |

|

+5mjpowell john bass Derek nigel breeze Trevor Amos 9 posters | |

| Author | Message |

|---|

Edward Pickering

Number of posts : 739

Age : 47

Localisation : Gloucester

Registration date : 2007-02-19

|  Subject: Re: Time,timing,time area ? Subject: Re: Time,timing,time area ?  Mon Sep 02, 2013 7:23 pm Mon Sep 02, 2013 7:23 pm | |

| Courtesy & Property Of Trevor Amos.  | |

|   | | Trevor Amos

Number of posts : 940

Registration date : 2010-08-13

|  Subject: Re: Time,timing,time area ? Subject: Re: Time,timing,time area ?  Mon Sep 02, 2013 7:50 pm Mon Sep 02, 2013 7:50 pm | |

| Morning Ed,

Many thanks for post the drawing .

The proportions of this bell mouth provide for a very efficient in-flow of air into the carb , and is certainly superior to most that are found on the carbs we use . If nothing else , it could fall into the category of fit, forget, for there is nothing better !

Like so many things in Bantam tuning , as the engine develops and revs rise so the flow rate improves and you will have the bell mouth to cope with this . Or put another way, at 6k it`s ok, 9k damn good, 11k brilliant, 13k off the scale !!??

Cheers, Trevor | |

|   | | nigel breeze

Number of posts : 358

Registration date : 2007-12-23

|  Subject: Re: Time,timing,time area ? Subject: Re: Time,timing,time area ?  Tue Sep 03, 2013 7:57 am Tue Sep 03, 2013 7:57 am | |

| Evening trevor, you may have read this already, its a quote by jan Thiel, i believe, with regard to air flows surrounding the bikes with and without fairings, could this be relevent for even the aircooled bantam?

"Some time ago engines mostly breathed air warmed by the radiator.

And do'nt forget the exhaust pipes!

Inside the fairing they heated the air quite a lot.

Putting them outside the fairing you lost revs.

The best solution was outside the fairing, but shielded from the airstream.

A friend of mine once tested his MBA 125 on a dyno. With and without fairing.

With fairing he lost 7HP!

So when I once had the opportunity of wind tunnel testing we looked at this.

There proved to be a quite big depression at the carburetors, at a wind speed of 120km/h

This depression would of course have been even bigger had the engine been running!

The airbox resolved all these problems.

The bigger the better I heard at Aprilia!

Mostly there is not enough room at the bike however" | |

|   | | Trevor Amos

Number of posts : 940

Registration date : 2010-08-13

|  Subject: Re: Time,timing,time area ? Subject: Re: Time,timing,time area ?  Tue Sep 03, 2013 7:48 pm Tue Sep 03, 2013 7:48 pm | |

| Nigel,

Yes I have seen that quote, and to add to that I was recently reading a history of the Van Veen Kriedler . The engineers back then had similar problems, when the pipe was inside the fairing power dropped, and the engine ran hotter, placing the pipe outside lost power through heat loss messing with the effective lengths . Fitting an air box, putting the pipe back inside the fairing reclaimed the power on the dyno, but the extra bulk of the air box increased the frontal area of the bike and top speed dropped!

Kenny Roberts and his team were testing at Daytona on the 750 Yam. after much fiddling around with putting the fairing on and off they sent the bike out less the lower half , revs went up by 300 at peak , replacing the fairing dropped the revs . Conclusion, heat from the mass of ex. pipe work inside the fairing was ingested and dropped the power level !

There are a lot of Bantams with their ex. pipes running right along side the barrel and carb. Considering that the pipe at that point is probably at a temperature of 400*c , the scope for inhaling that heat, and preventing cool air getting to the barrel fins it never ceases to puzzle me as to why this is done. So my advice is to allow a lot of cooling air to access the engine, it always pay dividends. Looking at a lot of lap times with speeds in the 60mph average it might be argued that the streamlining benefits over power to weight ratio are dubious and more overall benefit could be derived from binning the lower piece of the fairing .

Air cooled, highly stressed engines need a lot of external cool, air flow , and a lot of fuel inside to keep them safe !

Cheers, Trevor | |

|   | | john bass

Number of posts : 1748

Age : 95

Localisation : Bensberg, Germany

Registration date : 2006-12-06

|  Subject: Time to -- Subject: Time to --  Tue Sep 03, 2013 10:31 pm Tue Sep 03, 2013 10:31 pm | |

| Time to ban fairings -- or exhaust pipes -- only joking, of course! yet a well-designed fairing would not induce such difficulties and why not fit the radiator behind the engine....

OK OK! so I´ll shuddup!

Cheers!

PS I know a secret way of keeping induction air cooler... | |

|   | | Derek

Number of posts : 1065

Age : 63

Localisation : worcestershire

Registration date : 2007-06-15

|  Subject: Re: Time,timing,time area ? Subject: Re: Time,timing,time area ?  Wed Sep 04, 2013 4:36 pm Wed Sep 04, 2013 4:36 pm | |

| Hi John

You know a way! of keeping air cool, Im sure there are many different ways.!

That is exactly the type of comment I did not expect from you, perhaps you could share what your talking about so we can comment/agree/disagree or disregard.

| |

|   | | john bass

Number of posts : 1748

Age : 95

Localisation : Bensberg, Germany

Registration date : 2006-12-06

|  Subject: Oooh Aaah! Subject: Oooh Aaah!  Thu Sep 05, 2013 3:40 am Thu Sep 05, 2013 3:40 am | |

| Ooooh Aaaah! I should not have said `secret´... The "ways" were never secret -- just hidden away like.

Perhaps it was just the Divvil in me that knew there´d be an answer if I said, "Secret"....

And when I said, "cooler", I meant the air would be warmer if it was NOT PURPOSELY directed from the front of the fairing as in fish-streamlined record-breakers of pre-war days, or the `Dustbin´ fairings of early fifties. Whilst the makers of these fast machines were proud to show them streamlined -- or naked -- they frequently left out little details that helped with their success.

We discussed it on here earlier -- not as carb-inducted-air -- it was when we were discussing Air-Cooling generally. There was only your response to installing baffles inside the fairing since water-cooling seemed the favourite way to go....

Its just a matter of persuading air in front of the motorcycle to not mix with warm air streams that hug the warm engine and there have been a number of ways of doing this including the Triumph of Harry Bostock -- and others -- installing the head back to front. The neatest way is having baffles inside the fairing that direct the airflow from holes alongside the front number plate -- along the inside surface of the fairing to then direct the COOLER air at the carb intake -- or the easiest way is to use large-bore, thin-wall plastic*** tubes....

Even then a lot of people say the gain from this is not worth the bother ....

Cheers!

***there are some with heat-insulation covering.... | |

|   | | Derek

Number of posts : 1065

Age : 63

Localisation : worcestershire

Registration date : 2007-06-15

|  Subject: Re: Time,timing,time area ? Subject: Re: Time,timing,time area ?  Thu Sep 05, 2013 9:04 am Thu Sep 05, 2013 9:04 am | |

| the gain for plastic pipes on an air cooled engine is most deff worth the effort, I certainly disagree with anyone who would suggest otherwise, cool air ducts work" fact.

but a "good re-direct John"!!

Derek | |

|   | | mjpowell

Number of posts : 1074

Localisation : Lincoln England

Registration date : 2006-12-09

|  Subject: Re: Time,timing,time area ? Subject: Re: Time,timing,time area ?  Sat Sep 07, 2013 3:41 am Sat Sep 07, 2013 3:41 am | |

| A question for Trevor or anyone else?

Ref different port timing for A,B transfer and boost ports on a reed valve bantam:-

Do you think the port timings? or angle of entry into the cylinder to be more important?

By having a steeper entry - you have to a degree? lowered the port?

Regards Mike

| |

|   | | Trevor Amos

Number of posts : 940

Registration date : 2010-08-13

|  Subject: Re: Time,timing,time area ? Subject: Re: Time,timing,time area ?  Sun Sep 08, 2013 7:13 am Sun Sep 08, 2013 7:13 am | |

| Taking the last part first, a fully profiled port /duct flowing efficiently will always take precedence over just timing, so timing per se is not the be end and all end of trans. porting !

The popular concept of trans. gas flow is that of streams converging at the rear of the cylinder , flowing upwards , displacing spent combustion residues then filling the combustion chamber, with little charge exiting the ex. port . The real question here is how the upward axial flow is achieved without the whole column collapsing prematurely toward the ex. port , preventing that is the job of the upward/rearward angled A port . I think all Bantams use domed pistons so it makes absolute sense to at least use the crown radius to assist flow and use the coanda effect to allow flow to cling to the crown and offer cooling assistance .

Transfer gas has mass and velocity and when the streams collide at the rear of the cylinder their kinetic energy will convert to potential energy and that of static pressure. This will ensure that the fresh charge maintains it`s density and minimise mixing with residuals, importantly the rising column must retain enough impetus to rise vertically to the head.

The big advantage of a five port reed arrangement is that directional control of gas streams can be choreographed to flush out spent gas, maintain the upward trajectory of the gas column and leave the combustion chamber full of pure combustible gas and that always make good power over a wide range .

The geometry of the port outlet should have the lower floor angled at least to form a tangent to the piston crown, around 10*, and take care to make the edge of the piston flush with the port at BDC , this will allow the inner duct radius , leading to the cylinder, to have a large curve to enhance gas speed and minimise detachment . The upper edge should angle up to oppose collapse of the rising charge column . As an example, the RS Honda has 28* inclination and the Aprilia 22* to their respective A ports , the B ports are 5* and 12* with the C boost both at 55* . The job of the B port is to flush the lower cylinder clean and add to the mass transport of fresh charge , finally, the rear boost port keeps an upward momentum going and enhances the general flow regime .

The A port angles quoted are for 54mm stroke , obviously a 50mm stroke demands shallower angles and conversely a 58mm stroke will differ again . It might be worth doing some calcs here to establish a compound vector for the combined angles then modify to see if any improvement is made !

Port opening stagger can help also, with the first trans. port to open being the last to actually flow, high residual cylinder pressure being responsible , and if the rear most ports flow first the column flow gets into its stride just before the A port shows its helping influence.

This is a rather simplistic picture of what is a very complicated sequence of the flow dynamics events in a 2T cylinder and it is only comparatively recent investigative procedures that have revealed just what is going on . But I hope that a picture has emerged to assist those who like to experiment . One lesson I have learned is that compromises will inevitably have to be made to achieve a favourable outcome for the whole rev range package !

Cheers , Trevor

| |

|   | | Derek

Number of posts : 1065

Age : 63

Localisation : worcestershire

Registration date : 2007-06-15

|  Subject: Re: Time,timing,time area ? Subject: Re: Time,timing,time area ?  Sun Sep 08, 2013 9:12 am Sun Sep 08, 2013 9:12 am | |

| very interesting Trevor, Thank you for sharing that, out of interest you any relation to the kid in BSB 125 Honda by the name of "Booth-Amos".

And please comment on the significance of this: The Factory Aprilia specify a squish at 0.75mm with a 4 deg taper away from piston crown towards the central combustion chamber.

regards Derek | |

|   | | Trevor Amos

Number of posts : 940

Registration date : 2010-08-13

|  Subject: Re: Time,timing,time area ? Subject: Re: Time,timing,time area ?  Mon Sep 09, 2013 1:09 am Mon Sep 09, 2013 1:09 am | |

| Derek,

At first glance a .75mm squish clearance might seem a little wide, Steve consistently runs .65mm on the Honda RS, but what must be born in mind is that these are cold clearances! During running the Aprilia will produce more power , hence more heat, and the rod will also stretch, so the dynamic squish will compress to around .3/.4mm, to just avoid piston, head contact . The Honda, with its stubbier rod, and lower thermal loading has little in the way of similar problems . Also in the mix are the respective piston/rod weights, the bare pistons come in at 120g for the Aprilia and 130g for the Honda , the rod half for the Aprilia will be a lot more, as it is longer, and the special gudgeon pin has welded, sealed ends so will be heavier, stopping that lot at 13,500rpm, at TDC, will pull the rod out significantly!

A 4* taper on the squish band over the 50% band width area at 8mm, gives around .6mm, so providing a piston crown edge gap of, perhaps, .2mm and the .75mm clearance is easy to envisage .

Booth-Amos , I am not familiar with, but who knows there may have been an, indiscretion, in the past ?

Cheers, Trevor

| |

|   | | mjpowell

Number of posts : 1074

Localisation : Lincoln England

Registration date : 2006-12-09

|  Subject: Re: Time,timing,time area ? Subject: Re: Time,timing,time area ?  Mon Sep 09, 2013 1:38 am Mon Sep 09, 2013 1:38 am | |

| Thanks for that Trevor, just goes to show that knowing what you want

from your cylinder in port shapes dimension and timing and being

able to do it on a previously made cylinder is very nearly impossible!

But not to be put off where there's a will there's a way. The bit I'm going

to struggle with is the bottom of the transfer windows with the piston being

proud at bdc.

Ref transfers the first to open is the last to flow? What if they all open

together ? And if Aports are 30mm wide and B ports are 10mm wide

how does that impact on the whole thing?

Question for Derek - are we testing our bikes performance at Cadwell

against each other in the torque stakes? If not I'm up for pitting my machine against

yours on a rolling road?

Regards Mike | |

|   | | Trevor Amos

Number of posts : 940

Registration date : 2010-08-13

|  Subject: Re: Time,timing,time area ? Subject: Re: Time,timing,time area ?  Mon Sep 09, 2013 3:20 am Mon Sep 09, 2013 3:20 am | |

| Mike, quick question .

Is the reed engine we are talking about the one, taken apart, that you posted pics of on , I think, Facebook ? If yes then I have a clearer picture of the problem , the inverted barrel helps a lot ?

Cheers, Trevor | |

|   | | mjpowell

Number of posts : 1074

Localisation : Lincoln England

Registration date : 2006-12-09

|  Subject: Re: Time,timing,time area ? Subject: Re: Time,timing,time area ?  Mon Sep 09, 2013 3:47 am Mon Sep 09, 2013 3:47 am | |

| Hi Trevor just posted a picture on facebook of reed motor with cylinder at bdc

I'm hoping you can make out the large A port small B port with devcon in the

top a big-ish C boost port and my red pen marks for possible improvements?

This pic is old..

Regards Mike

Dan can you image on here please? | |

|   | | Trevor Amos

Number of posts : 940

Registration date : 2010-08-13

|  Subject: Re: Time,timing,time area ? Subject: Re: Time,timing,time area ?  Mon Sep 09, 2013 3:52 am Mon Sep 09, 2013 3:52 am | |

| That's great , thanks Mike, I`ll get on the case!

Cheers Trevor | |

|   | | Edward Pickering

Number of posts : 739

Age : 47

Localisation : Gloucester

Registration date : 2007-02-19

| |   | | mjpowell

Number of posts : 1074

Localisation : Lincoln England

Registration date : 2006-12-09

|  Subject: Re: Time,timing,time area ? Subject: Re: Time,timing,time area ?  Mon Sep 09, 2013 6:33 am Mon Sep 09, 2013 6:33 am | |

| Thanks for that Edward..

Trevor this cylinder being old has it A ports directed to the rear wall

the B ports looking very nearly at each other (rear wall) C port at an

Angle of 55*. The proposed mod in red ink was never done as it sprung

a big leak into the exhaust port at the end of 2007. Oh A & B ports point

To piston crown 0*

Cheers Mike | |

|   | | Edward Pickering

Number of posts : 739

Age : 47

Localisation : Gloucester

Registration date : 2007-02-19

|  Subject: Re: Time,timing,time area ? Subject: Re: Time,timing,time area ?  Tue Sep 10, 2013 1:27 am Tue Sep 10, 2013 1:27 am | |

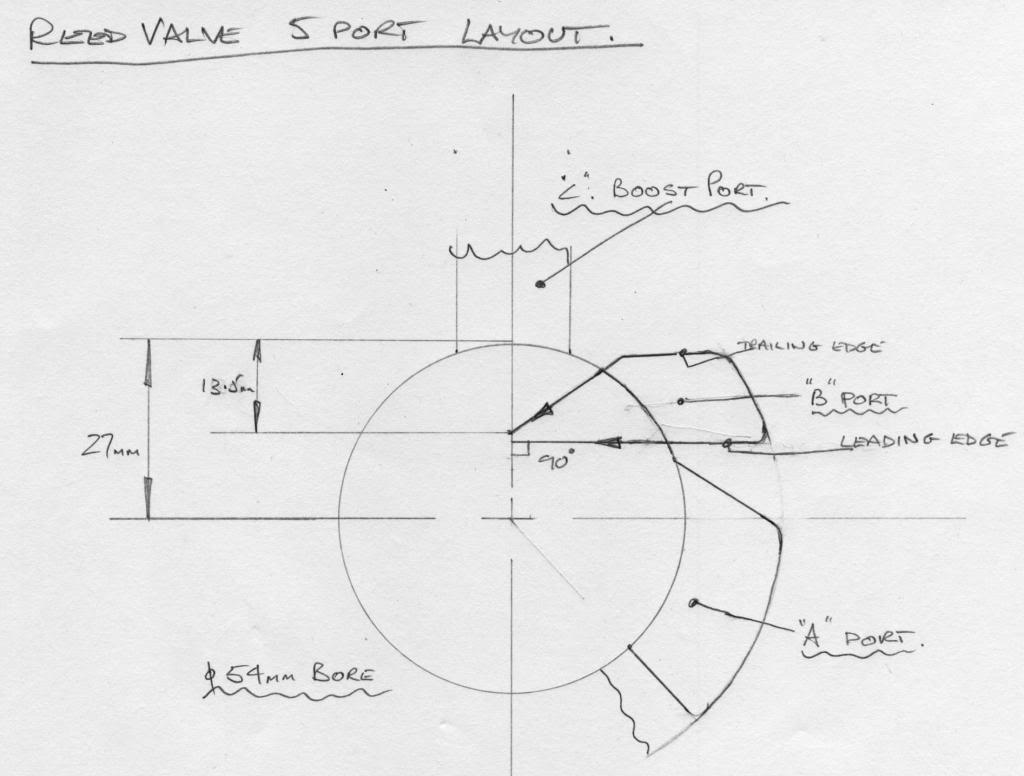

| Courtesy & Property Of Trevor Amos.  | |

|   | | Trevor Amos

Number of posts : 940

Registration date : 2010-08-13

|  Subject: Re: Time,timing,time area ? Subject: Re: Time,timing,time area ?  Tue Sep 10, 2013 3:40 am Tue Sep 10, 2013 3:40 am | |

| Mike,

I hope the sketch makes some sort of sense, by not having enough detailed info this is just representative and the text will make things a little easier to understand .

Don`t make the rear boost too wide, for at lower rpm it will flow sluggishly and we need some velocity to maintain the upward thrust to the gas column . Having tangential C ports facing each other, and at 90* to the cylinder axis, encourages the gas streams to crash into each other, lose their momentum, create masses of turbulence and shower the fuel mix all over the place ! Compounding the problem is the very small duct/port area with the same pressure ration applying to the B and A ducts. The smaller will flow very rapidly and will be into its stride while the A is thinking about it , such is the inertia disparity between mass contained in the the two ducts. Perhaps more importantly is the fact that with the two B streams engaged in battle right in front of the C port , the boost cannot flow efficiently for its progress is so impeded. Any coherent joining of these three streams is negated by their mutual interference, angling the trailing edge of the B port away from the boost and also upwards at, say 10*,resolves all of this conflict . Similarly, angling the leading edge of the B to impinge at 90* to the centre line widens the flow spread to cover more of the piston crown and interferes minimally with bulk port flow.

If it is feasible, widen the B in both directions, the 2mm toward the boost and also to the A leaving a narrow septum of 1mm, there is no thrust issue at the piston side and so the ring has ample support . Doing this, and modifying the duct walls to suit, takes the width to around 14mm which with a height of around 12.5mm you gain a massive 100sq/mm of area !

In truth, in the A port is too wide at 30mm , far better to have 5mm of this given to the B, together with duct volume. If you can get some good quality filler into the roof of the A to produce some axial inclination that also will help a lot . Now all of this is easy for me to say and damn difficult, I suspect, for you to do, but anything you can do with what you have is going to help and it is the torque level that is going to benefit the most .

Just one more thing, the proximity of the transfer port to the ex. port is minimal, the photo is a little unclear here, but this is just the situation that at lower revs will allow short circuiting to occur, particularly if the pipe is less than optimum for that rpm level . Again, judicious use of filler might help , true you will lose a little area but the potential benefit will out weigh the penalty, just one more compromise amongst the many!

Just my opinion of course, but it works for us !

Regards, Trevor

| |

|   | | mjpowell

Number of posts : 1074

Localisation : Lincoln England

Registration date : 2006-12-09

|  Subject: Re: Time,timing,time area ? Subject: Re: Time,timing,time area ?  Tue Sep 10, 2013 4:56 am Tue Sep 10, 2013 4:56 am | |

| Great thanks Trevor for your input, and taking the time to do some thinking.

Its a good job I didn't go for my mods as I would of taken the defector bit off

the rear edge of the B port. So that bit is best left on. Currently it is as your

diagram on that side.

The B port edge (near the A port) I dare not touch and will have to live with a 80*

angled to the rear wall.

I can do the 10* angled upwards B ports. But I can't make the B ports wider or

the A ports narrower. Are you suggesting filler in the A ports or the exhaust?

Which is a possibity ?

Because of all this I'm thinking :-

A ports 126* timing- 0*(piston crown)

B ports 124* timing- 10* angled upwards

C port 128* timing -55* angled upwards

with 190* Exhaust 360* Inlet Reed

Cheers Mike | |

|   | | Trevor Amos

Number of posts : 940

Registration date : 2010-08-13

|  Subject: Re: Time,timing,time area ? Subject: Re: Time,timing,time area ?  Tue Sep 10, 2013 6:25 am Tue Sep 10, 2013 6:25 am | |

| Mike ,

Apologies for the lack of clarity, I did mean the A port adjacent the ex. port , a bit of filler in there to increase the top corner rad will help to keep trans gas from the ex. port . Under certain conditions of revs and pipe geometry, losses can become significant .

Your proposed timings seem a good starting point and will provide valuable information to carry forward the development program .

You have your finger on the pulse of Bantam racing, far more than I have, so perhaps you can explain a little as to why so few people contribute to, or enquire about, the technical postings. I would have thought that tech tips would inspire riders to want to know more and ask questions, every one can learn from each other. I guess all riders would like that extra bit of power or reliability or better power spread and might get it by simply asking ?

Cheers for now, Trevor | |

|   | | mjpowell

Number of posts : 1074

Localisation : Lincoln England

Registration date : 2006-12-09

|  Subject: Re: Time,timing,time area ? Subject: Re: Time,timing,time area ?  Tue Sep 10, 2013 8:05 am Tue Sep 10, 2013 8:05 am | |

| Thanks Trevor, its easier to get filler to stick in transfers than exhausts I've found!

This cylinder is 'what it is' and was in the spares when my brother and I bought 2x

bikes from Tom and Ned. It was piston port 6 transferred 2 exhausts and was without

liner. I was 18 at the time (47 now) and had big ideas to make a reed valve like the Ned

Bantam but better! So a reed block was made and brazed on, I removed 2x transfer bridges to

make it 4t and Fahron Engineering made a liner to suit. So that's why the B ports are

small they are the rear pair of a set of 3 (6 holes)? I've had 24bhp from it in the past so hopefully

this rethink on the motor plus a new pipe may give more torque and with its inherent flaws

about the same power but a lot easier to ride?

I'll keep like an open blog on this motors progress in this form so folk can see how it is going

and see how it gets developed over time. I think sometimes it easier to get a fast bantam by

keeping things simple - the more ports you have the more chance you have of getting something

wrong.

Technical stuff on the forum, generally people want to know what others are doing but just because

others are doing it doesn't make it right? Plus a lot of people don't understand or can't follow it and

don't post because they don't want to appear daft. Shame really the more stuff that's out there the

better!!

Regards Mike

| |

|   | | Derek

Number of posts : 1065

Age : 63

Localisation : worcestershire

Registration date : 2007-06-15

|  Subject: Re: Time,timing,time area ? Subject: Re: Time,timing,time area ?  Tue Sep 10, 2013 5:05 pm Tue Sep 10, 2013 5:05 pm | |

| A fast bantam with two transfers will always struggle to compete with a fast bantam with four transfers, the sad thing is there are few people capable of making a 4 transfer water-cooled bantam fast, and reliable enough to win races. and while this has been ignored.

So I say it again- weight does play a very big part in Bantam Racing, no matter how good the engine or riders ability, it can be very difficult for riders of similar ability with bikes of equal or more power and torque to overcome a bike with less power or torque, with a light rider on board, with six gear this would be less of a problem but would still be there. | |

|   | | john bass

Number of posts : 1748

Age : 95

Localisation : Bensberg, Germany

Registration date : 2006-12-06

|  Subject: Can´t contribute any engíne technology... Subject: Can´t contribute any engíne technology...  Tue Sep 10, 2013 6:37 pm Tue Sep 10, 2013 6:37 pm | |

| Can´t contribute any engine technology `cos you are streets ahead Mike but I can just add that W/g -- rider´s mass -- as Derek mentioned is an immediate discourager of a would-be Bantam racer who weighs over 11stone.

But Bantam racing saved me from dying of overweight diseases... What a diet: black coffee for breakfast, apple (One) & cheese for lunch -- a steak and salad for dinner. No beer -- gin & tonic as alternative and I hate G&T....

I got down from around 16stone... (grub & booze on Simms Expenses) to 12stone 3lbs in 6 months and was so weak I was so exhausted that if Icarus-1 didn´t start on first run&bump I couldn´t do it again... so I was well pleased to ride Anyd Boyle´s 250 ABS with Alpha "Works" motor & FIVE gears at 12stone 7lbs...

The Intermediate Class -- where I did manage wins (in the wet) kept me going with the Bantam but I was always frustrated in Senior races knowing I was in there to race for 12th place or so...

Cheers! | |

|   | | Sponsored content

|  Subject: Re: Time,timing,time area ? Subject: Re: Time,timing,time area ?  | |

| |

|   | | | | Time,timing,time area ? |  |

|

Similar topics |  |

|

| | Permissions in this forum: | You cannot reply to topics in this forum

| |

| |

| |