|

| | exhaust |  |

|

+3Edward Pickering Trevor Amos nigel breeze 7 posters | |

| Author | Message |

|---|

nigel breeze

Number of posts : 358

Registration date : 2007-12-23

| |   | | Trevor Amos

Number of posts : 940

Registration date : 2010-08-13

|  Subject: Re: exhaust Subject: Re: exhaust  Fri Apr 04, 2014 7:50 am Fri Apr 04, 2014 7:50 am | |

| Oh look come on Nigel, even us Bantam boys have to maintain a certain aesthetic standard for our design work and execution!

Such an acute join will disturb gas particle flow, and ill-timed pressure wave reflections, for both out-going and reflected waves, will both mess with gas speed, reduce temperature and leave the calculated timed length will be awry. Can you manage, say, three short angles for a gentler transition to a curve? If not, what I have done in the past is to remove the bottom of the angle, and put in a curved patch and repeat the same at the top, leaving the sides still joined, it then is a reasonably simple matter to maintain the correct diameter, not perfect but a great improvement, might need a bit of heating and tin bashing though.

At the risk of getting into trouble, I do have some reservations over the dimensions of the pipe you are replicating. If I read the published dimensions correctly, it seems proportioned less favourably than it could be. That is typically seen on Blair type pipes where the diffuser ends up shorter than the ex.duct and header. What is needed is a nice long, low pressure pull from the cylinder, at the exhaust port, all around bdc when the transfers are open, too long a header delays the onset of this much later into the cycle. This is paid for in reduced power in the band width. The end of the diffuser is pretty much on the money when measured from the piston face, as a proportion of the tuned length, but that also assumes that the tuned length is correct in the first place?

A 1% error in 900mm is 9mm, 5% is 45mm, over 1-3/4" that is a very long way in ex pipe terms, small percentages, big effect!

Trevor

| |

|   | | nigel breeze

Number of posts : 358

Registration date : 2007-12-23

|  Subject: Re: exhaust Subject: Re: exhaust  Fri Apr 04, 2014 8:26 am Fri Apr 04, 2014 8:26 am | |

| Cheers for reply Trevor...ive ditched the bend tonight.. Gonna pull the bend out by getting the curve through the end of the header into the divergent cone...look like aprilia shape.�� Will it be any good anyway?? You can only try �� | |

|   | | Trevor Amos

Number of posts : 940

Registration date : 2010-08-13

|  Subject: Re: exhaust Subject: Re: exhaust  Sat Apr 05, 2014 2:19 am Sat Apr 05, 2014 2:19 am | |

| Sounds like you have a scheme in mind Nigel, don`t you just love it when a plan comes together !

There is one other thing I should have pointed in the previous post, but I couldn`t read my own scribbled notes. That was, with a short diffuser having two components and the larger angled cone second, reflections from the latter, having a larger amplitude, therefore speed, can overtake the former, combine with it, and cause such havoc with a shock wave, that efficiency drops, together with power. Maybe it would be better to have the reverse situation where the shallower angle helps, but doesn`t dominate, and then transitions to the parallel part. This layout would probably give more volume to the pipe for the same maximum diameter, and overall length.

Hope you can post a pic. or two of the revised construction, that is a pretty swish workshop you have there, complete with toaster, kettle, posh work bench and multi power points! Most have to make do with a grungy old garden shed.

Trevor

| |

|   | | nigel breeze

Number of posts : 358

Registration date : 2007-12-23

|  Subject: Re: exhaust Subject: Re: exhaust  Sat Apr 05, 2014 8:41 am Sat Apr 05, 2014 8:41 am | |

| Trevor, no point pussy footing about.. you got to have all the basics.. work top and power points kettle and toaster.. you never know when tea and toast are required to increase the manic obsession .  (Good job i didnt pan round to include the microwave and three days worth of washing up!! ) so you recon i should delete the short cone in front of the belly section? and carry the the section after the header pipe upto the belly section?.. Derek asked me about how big the volume in the system was generally and with the small stinger outlet at 23.5 mm i summised that this was to keep the heat in to compensate for this,( im sure that 32mm on a 175 was considerd the norm to keep the siezures at bay) also the compression ratio at 8.9. Like you say that blair formula exhausts may be only starting points, having to use other peoples set ups and measurements is the only other way. Tuned length of the system? it seems that the heat produced inside the exhaust is a guess at best, unless you have the equiptment to determin this, so perhaps only a dyno test will show any faults in this system that need adressing. i will show my changes to this system im knocking up for people to view and comment on, or at least you, as no one else has a view or opinion on this, or so it would seem......  | |

|   | | Trevor Amos

Number of posts : 940

Registration date : 2010-08-13

|  Subject: Re: exhaust Subject: Re: exhaust  Sat Apr 05, 2014 7:44 pm Sat Apr 05, 2014 7:44 pm | |

| Nigel,

Picking up your last comment first, I waited until over a week had elapsed, during which there was no active contribution to the Forum here, before I got Ed to post the April1st spoof, just in an attempt to keep things alive! I`m not alone in finding it strange that Bantams go the grid with this web address emblazoned across their fairings, extolling the virtues of Bantam racing and yet the site is effectively inactive. It then seems that when any sort of relevant announcement is made , social media takes priority! So at the moment Nigel it is just you and me left as the standard bearers, Allan, you administer the site, can you offer any remedial prescription or diagnosis or, is it simply that every one else content?

I`ll put some figures on paper over the weekend which will look at this pipe stuff, I know not every one enjoys playing with formulas and the like, but as, unusually, as we have the answer in the tuned length, we can do a deconstruct to find the significant input numbers, to see if it all stacks up favourably of not.

Crikey, I hope that won`t mean you have to make yet another pipe up!

Say cool and loose, Trevor | |

|   | | Edward Pickering

Number of posts : 739

Age : 47

Localisation : Gloucester

Registration date : 2007-02-19

|  Subject: Re: exhaust Subject: Re: exhaust  Sun Apr 06, 2014 2:14 am Sun Apr 06, 2014 2:14 am | |

| Good Afternoon Nigel,

How did you go about making your exhaust and what thickness of metal did you use?

Kind Regards

Eddie | |

|   | | nigel breeze

Number of posts : 358

Registration date : 2007-12-23

|  Subject: Re: exhaust Subject: Re: exhaust  Sun Apr 06, 2014 4:15 am Sun Apr 06, 2014 4:15 am | |

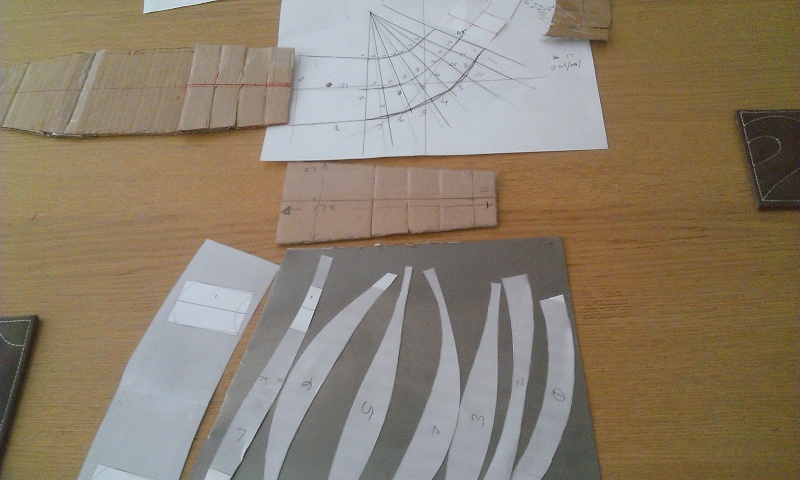

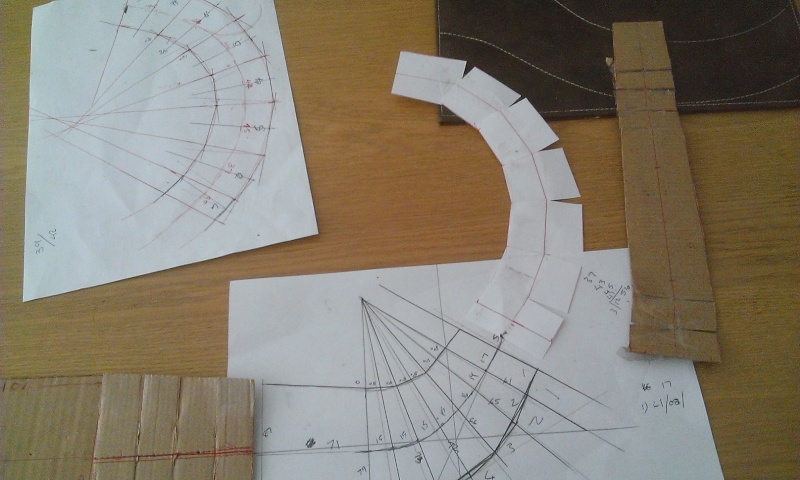

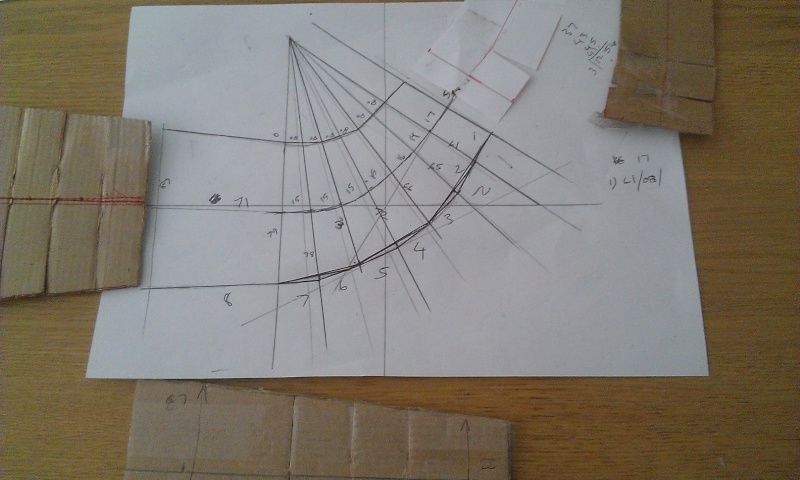

| Trevor, ill hold fire for now, maybe some modification?? was going to crack on with it today. Looks like ive got to dig that garden pond instead, now ive no excuses  Eddie,nice to hear from you again, its been a bit easier so far than the first two exhausts ive made. Still got the cone layout program which is vital and then the heads up on dimensions from the snowy 175 engine post. I tried to make the first two exhausts with 1mm sheet steel but i found it just a bit too stiff to maniplulate into the cone shapes. This time ive managed to get hold of some 0.8mm which ive found alot easier to deal with. I made a cardboard template to the required dimensions, held it under the engine and tried to get the basic shape of the run of the pipe by cutting into the template centerline and bending the template to form the bends required cellotaping together to hold in place. Once i was happy with that i traced around that shape to make another template complete with these bends.  from this to this  I I felt the bends at the start were too tight so reshaped this header section for a better sweep  I then traced around this onto a piece of paper and carved it up into sections to form the cones needed to make this shape  I used a protractor to measure the degrees required to get the cones to sit together nicely, most where around 12 degrees others slightly larger and used the cone layout program to make the paper templates. As you can see from the pictures previously that ive changed some of the bends again to keep the system more smooth, rather than tight sharp bends. ive managed to form the cones around steel pipe as ive not got any rolls, also ,as ive only got a mig welder, which isnt good to weld this together with ( blows holes though the sheet metal), ive tacked the cones together with braze wire with the mig welder ready for welding at some stage    I found that cutting the sheet metal relativly easy but the shears do curle the metal at the edges and this needs to be adressed else the joints are not quite right. Wells thats as far as ive got for now .... when its finally done ill post a picture.. | |

|   | | dansofield550

Number of posts : 367

Localisation : gravesend kent

Registration date : 2011-10-23

|  Subject: Re: exhaust Subject: Re: exhaust  Sun Apr 06, 2014 5:36 am Sun Apr 06, 2014 5:36 am | |

| That all looks a bit like hard work, I used a program to calculate the pipe dimensions etc then another to draw it into cones for my cad program then lasered the parts , I to used 0.8 . Just a point on replies on the forum, mostly posts are by non racers | |

|   | | john bass

Number of posts : 1748

Age : 95

Localisation : Bensberg, Germany

Registration date : 2006-12-06

|  Subject: Ex -- very ex-Raceers Dan,,,, Subject: Ex -- very ex-Raceers Dan,,,,  Sun Apr 06, 2014 6:34 am Sun Apr 06, 2014 6:34 am | |

| Ex racers Dan -- very ex.... almost total-ex as in expired.... Had my share of making pipes. Spouted on here -- ages ago about it and the extendable parallel portion I used during Brands practising which didn´t prove an awful lot for a great amount of work but was worthwhile in establishing the seemingly right one [(-- or two -- or three...)] way(s) to go. Well, not exactly: when it came the the 250 ABS Andy gave me the dimensions direct off his D.... computer. We should hit 10,500 rpm -- a thousand more revs and have a better torque curve -- ... It looked a bit odd when compared with the great number of Bantam pipes I had made but I did it and went to Brands thinking the ABS was going to shock the world. It was a hell of a day I kept dropping the gear-ratios and the engine just went burr-burrr pop-pop--pop burr-burr -- just refused to come onto the pipe and run clean -- so I put the original pipe back on and bad-temperedly had a good half-hour blast. A lad who´d `diced´ with me on his Production bike came over and said he was highly impressed -- So, based on that very subjective measurement I raced the ABS with the same pipe after that... Several times it was second Brit-bike home and had the legs of a Greeves Silverstone and could have done better with another pilot....

Speaking of measuring pipe volume you (can) use a small bath plug for the tail pipe -- or a bigger one for the exhaust junction end -- , fill the pipe with water and measure what comes out using a calibrated bucket or repeatedly filling one of those jugs used for measuring baby milk. When making a pipe you can do it with each componet part before welding say the nozzle to to the tail-pipe and parallel portion. It saves wearing out the grey-matter and making silly mistakes on the computer....

Yawnnnnn!

Time for bed.

Anyone got any news on what happened at Cadwell 28th March 2014,,,,?????

Cheers! | |

|   | | Trevor Amos

Number of posts : 940

Registration date : 2010-08-13

|  Subject: Re: exhaust Subject: Re: exhaust  Sun Apr 06, 2014 7:51 am Sun Apr 06, 2014 7:51 am | |

| Now that is most impressive Nigel, just goes to show what can be done with limited facilities, determination and an intelligent approach to a tricky problem. Are you up for taking orders, bespoke pipes must have a lucrative future for you? Years ago I made paper cone patterns using a bit of geometry, a long trammel and drawing board, took a time, but that was cheap enough, enjoyable and I learned a lot.

Trevor | |

|   | | nigel breeze

Number of posts : 358

Registration date : 2007-12-23

|  Subject: Re: exhaust Subject: Re: exhaust  Mon Apr 07, 2014 12:15 am Mon Apr 07, 2014 12:15 am | |

| Dan, thanks for your reply, looks like you have access to some good equiptment. Laser cutting, so much easier and obviously very accurate. Ive had a couple of goes with the exhaust design programs and also trying to calculate by the math formulas, they seem to give conflicting sizes and as you probably can see from my attempts to at least keep the tuned length , smooth lines and still fit, in my own little way, are as you say hard work. Even more from passed experience in having ago, very dissapointing when it seems not to be quite right . My last attempt , an up and over, measurements taken from the sprinter write up on the web site , seemed to work well with the rest of the set up, eventually. My welding attemps though where really poor and it leaks all over the place.I take my hat off to those who can produce exhausts by hand ,with beautifully welded joints, i really do. As to your point that only non racers use the site( or ex racers) i never really noticed before  , but your right to a point, as i would fall into this catagory, maybe i should keep my mouth shut with regard to this in future, all the best for the coming season. Trevor, just my attempts at being as accurate as possible.Not sure i can produce the top quality required to knock em out though  Derek had some really nice pipes made by Mick Abbey which worked well for him..... dinners on the table , all the best . | |

|   | | dansofield550

Number of posts : 367

Localisation : gravesend kent

Registration date : 2011-10-23

|  Subject: Re: exhaust Subject: Re: exhaust  Mon Apr 07, 2014 1:25 am Mon Apr 07, 2014 1:25 am | |

| I'm in that category too Nigel!!, people racing currently rearly post it seems, not sure why, maybe to busy or summit | |

|   | | mjpowell

Number of posts : 1074

Localisation : Lincoln England

Registration date : 2006-12-09

|  Subject: Re: exhaust Subject: Re: exhaust  Mon Apr 07, 2014 1:41 am Mon Apr 07, 2014 1:41 am | |

| Nigel ref an exhaust pipe for your 175 motor rather than starting again from scratch copy the Snowy pipe and try and get your port timings the sameas Snowys and it should work. Snowy holds the Cadwell lap record so it can not be too bad!

Ref forum a great place to ask questions and glean information but most of your answers will come from ex-racers (good job they still have an interest and an input) as the current racers are doing it for real and are in their workshops/sheds.

Facebook is a good way to share pictures and create interest in the class which is very fast moving, there are 5 administrators 3 of which are current racers and 2ex bantam racers. Also George Todd is quite active on it.

On the forum some current racers have left due to abusive and critical messages being posted. I hope they (the riders) return in the near future and start posting again..

See you at Anglesey Mike | |

|   | | john bass

Number of posts : 1748

Age : 95

Localisation : Bensberg, Germany

Registration date : 2006-12-06

|  Subject: Mike P... don´t be shy..... Subject: Mike P... don´t be shy.....  Mon Apr 07, 2014 5:56 am Mon Apr 07, 2014 5:56 am | |

| Hey Mike -- tell us what happened at Cadwell 28th March 2014 -- don´t be shy.

I have tried getting on Facebook -- they won´t have me -- they give me a new password and when I use it they tell me I am not me.

Funny thing is I am getting a bit absent-minded -- Oh heck! where´s me teef.....

Cheers!

JayBee.... | |

|   | | mjpowell

Number of posts : 1074

Localisation : Lincoln England

Registration date : 2006-12-09

|  Subject: Re: exhaust Subject: Re: exhaust  Mon Apr 07, 2014 6:34 am Mon Apr 07, 2014 6:34 am | |

| I didn't see anything at Cadwell John as I was at work and got there late to watch but was to busy chatting to folk.

In brief on the grapevine... Graham Newman clutch gremlins but got some laps in.. Phil Betty happy with his bantam so did most sessions on his 350 Triumph.. Rob Duesbury a fall and a seizure but not sure in which order and all on his back to front water cooled motor not his ex Ian Scutt championship winning air cooled motor.. Mick Potter an off and a nasty looking finger injury.. Michael and Robbie Brown? I'm not sure lots of bike bits spread on the paddock floor mixed in with Robs car boot and bric a brac store and his bags for his Butlins weekend.. Attention now turns to Anglesey next weekend... | |

|   | | Edward Pickering

Number of posts : 739

Age : 47

Localisation : Gloucester

Registration date : 2007-02-19

| |   | | john bass

Number of posts : 1748

Age : 95

Localisation : Bensberg, Germany

Registration date : 2006-12-06

|  Subject: Exhausting...! Subject: Exhausting...!  Tue Apr 08, 2014 6:06 am Tue Apr 08, 2014 6:06 am | |

| Well done Trevor!

Your straight pipe drawing makes it look like there are -- effectively -- three diffusers. We always used a parallel pipe for first section and I see you go from 37 (1.46ins) to 56 (2.2ins) -- which seems quite precise -- over 229 (9.3ins) length which is curved... and perhaps isn´t all that smooth (as a parallel section would be) I wonder how much difference that makes over a parallel pipe ? I remember asking that same question yonks ago and getting the answer that the difference from parallel to tapered header was too small to be bothered with....

Anyway, I think my mentor and engine tuner was always looking at my body weight and tuned for high torque rather than high speed horsepower. We were, of course using contact breaker and battery & coil ignition which didn´t always allow for high revs anyway. Anyway he was highly delighted when I won my first Novice race at Cadwell with a locked clutch (it stopped slipping but would not free off...) on the last lap. Most important aspect -- of it all -- was that we were looking for a jockey and the right material didn´t turn up so instead of development-practising at Brands I rode it in Bantam races. RODE being the right word in Senior Bantam Class races....

One could assume the great omnipotent (way up there) designed some of us to be disadvantaged for Bantam racing by our body-weight and others of us, a shortage of grey-matter to not be able to emulate Prof Blair but thick & dumb as some of us were, we still managed actual racing -- AT TIMES!

I cannot recall the man´s name who made resonant pipes using a pressuried hydraulic system. He and his son were both bike racers and his workshop was in Romford. I went there one day in the early eighties to use his lathe and asked how he actually did it but he told me it was a trade secret-- anyone, out there (here...) know who I mean. He went off to Australia some time in the eighties...

Cheers! | |

|   | | Trevor Amos

Number of posts : 940

Registration date : 2010-08-13

|  Subject: Re: exhaust Subject: Re: exhaust  Tue Apr 08, 2014 8:04 am Tue Apr 08, 2014 8:04 am | |

| Evening John,

The front pipe or header as they are now referred to, is intentionally a shallow taper for we don`t want wave reflections returning to the exhaust port to impede gas coming out, shallow tapers don`t reflect , power always drops when header tapers creep upwards for just this reason. Using a parallel pipe would mean a very acute taper then for the first part of the diffuser, what we need is a long, smooth continuous pull and the slightly greater taper at the end of the diffuser helps to keep the energy levels up a bit but over a shorter duration. And if you`re very clever the diff can stop working, at the parallel section, as the transfer ports close. There is no gain in pulling good stuff out of the cylinder any more than is necessary. If you can imagine the flowing tapers of a brass musical instrument then that is a good analogy. Conversely blown pipes come off unfavourably when compared to the traditional, individual cones for the smearing of the joints reduces their impact and efficiency, and time is always too short in trying to get the good waves going!

Nostalgic stuff John, Senior Bantam races were certainly hectic in those days, 40+ starters, screaming down the Norwich straight praying that the engine wouldn`t lock up, always a group somewhere to dice with, ah, I can still smell the Castrol R!

Ed, many thanks for getting the article to the Forum so quickly!

Trevor

| |

|   | | nigel breeze

Number of posts : 358

Registration date : 2007-12-23

|  Subject: Re: exhaust Subject: Re: exhaust  Tue Apr 08, 2014 8:32 am Tue Apr 08, 2014 8:32 am | |

| Trevor, thanks for your time and effort regarding this exhaust information. Looks like i have another pipe to choose from.. keep me busy, thanks again.  | |

|   | | dansofield550

Number of posts : 367

Localisation : gravesend kent

Registration date : 2011-10-23

|  Subject: Re: exhaust Subject: Re: exhaust  Tue Apr 08, 2014 7:28 pm Tue Apr 08, 2014 7:28 pm | |

| nigel , i have a dxf file of the cones i used, i plotted two exhausts with the software , one for supposedly high torque the other for high power, if you can view these files i'll send them to you, | |

|   | | nigel breeze

Number of posts : 358

Registration date : 2007-12-23

|  Subject: Re: exhaust Subject: Re: exhaust  Tue Apr 08, 2014 8:10 pm Tue Apr 08, 2014 8:10 pm | |

| Dan, that would be great..�� | |

|   | | dansofield550

Number of posts : 367

Localisation : gravesend kent

Registration date : 2011-10-23

|  Subject: Re: exhaust Subject: Re: exhaust  Wed Apr 09, 2014 11:55 pm Wed Apr 09, 2014 11:55 pm | |

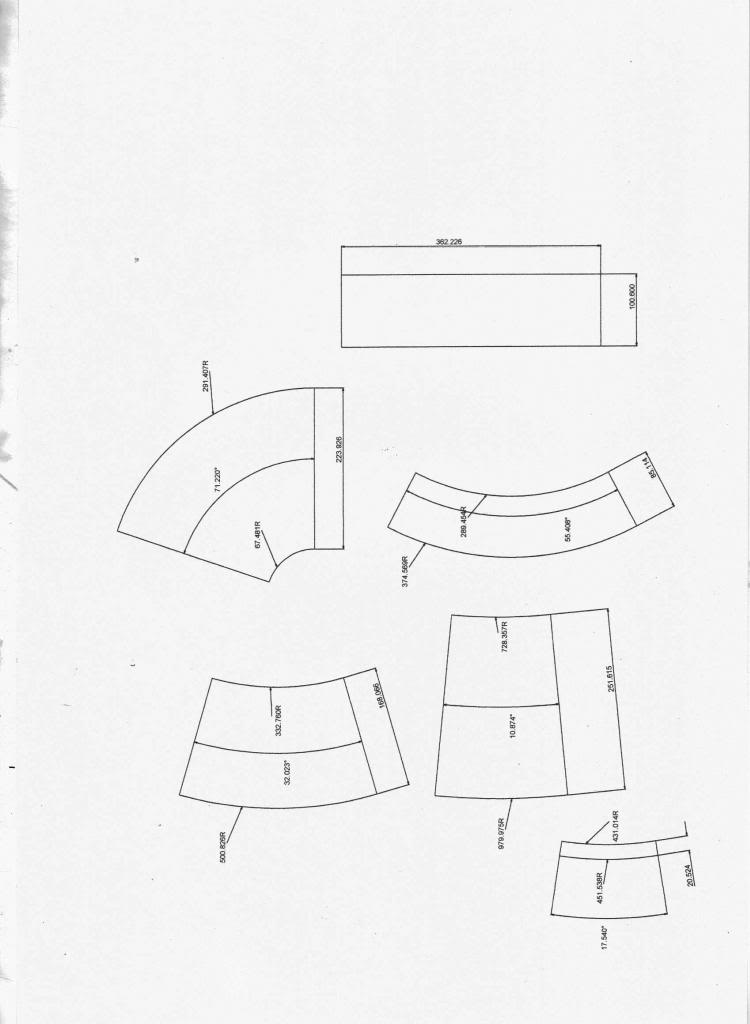

| nigel , if you let me have your email address i'll send the dxf files as i cant attach them here , in the mean time heres a print out of the cones with some dimentions .  | |

|   | | john bass

Number of posts : 1748

Age : 95

Localisation : Bensberg, Germany

Registration date : 2006-12-06

|  Subject: Just remembered.... Subject: Just remembered....  Thu Apr 10, 2014 5:24 am Thu Apr 10, 2014 5:24 am | |

| Thanks Trevor!

I can understand that bit of simple know-how -- which I never used...

Not being nitt-picky -- I hope! Just want to be in among technical debate (Some call it rattling the cage -- other that the dummy has just been thrown out of the pram....) on things I missed or didn´t round to doing nearly half-a-century ago. In any case during those times I was so busy I really didn´t have time to be more than the jockey and Gofer for our so-called `team´.

Some of the `headers´ I´ve seen are bent by cutting at an angle, the pieces turned through 180° and welded -- several times, in this manner -- which surely means the `rugosities´, or discontinuities would cause some disturbance to flow which a purpose bent parallel would not have ....

I just remembered a Professor-Doctor engineer here in Deutschland using the word `Rugosities´ during an engineer meeting and not finding the word in my Oxford Dictionary I thought it must have been a word he´d invented. It brought back the memory and I just had to use it....

The discontinuities: ie., the sharper angles than a curve -- wouldn´t they have an effect?

Cheers!

John-Boy. | |

|   | | Trevor Amos

Number of posts : 940

Registration date : 2010-08-13

|  Subject: Re: exhaust Subject: Re: exhaust  Thu Apr 10, 2014 6:25 am Thu Apr 10, 2014 6:25 am | |

| Rugosities, now I like that John, much more descriptive than discontinuities and I can even pronounce the word, always struggled with discon..... You are spot on, any small defect will cut down on wave speed and slow particle flow. In the header where temperatures and speeds are still high the effect is all the more serious. Testing at Aprilia found that the gently curved, tapering front pipe of the later spec engine produced less power than the reversed exhaust port engine with a straight out pipe. Some of the serpentine pipes with acutely angled joints on current machines must be self-defeating, particularly when heat radiates to the carb, head and barrel, double whammy.

Topically, part of the early season success of the turbo F1 Mercedes is due to the fact that the turbo is divided in two taking the exhaust heat away from the inlet to the other end of the engine. Cooler, denser inlet charge means more power, for free. A lesson to every one? Keep cool!

Trevor | |

|   | | Sponsored content

|  Subject: Re: exhaust Subject: Re: exhaust  | |

| |

|   | | | | exhaust |  |

|

Similar topics |  |

|

| | Permissions in this forum: | You cannot reply to topics in this forum

| |

| |

| |