| | Gearbox Nasties... |  |

|

|

|

| Author | Message |

|---|

mjpowell

Number of posts : 1074

Localisation : Lincoln England

Registration date : 2006-12-09

|  Subject: Gearbox Nasties... Subject: Gearbox Nasties...  Wed May 25, 2011 5:27 am Wed May 25, 2011 5:27 am | |

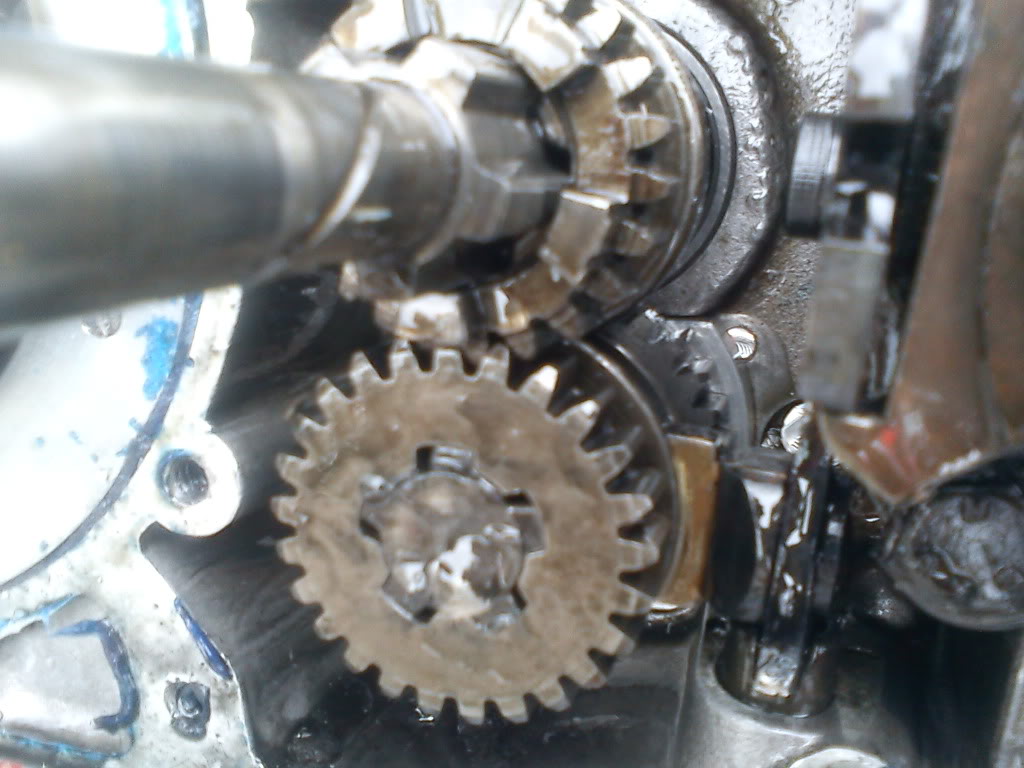

| Robin exploded his gearbox on Saturday morning - its the heavy flywheels.... And I snapped a layshaft in Saturdays second race and got away lightly- bike was up and running for me to crash in practice Sunday morning.... Here's a piccy....  | |

|

| |

john bass

Number of posts : 1748

Age : 95

Localisation : Bensberg, Germany

Registration date : 2006-12-06

|  Subject: Broken layshaft... Subject: Broken layshaft...  Wed May 25, 2011 6:06 am Wed May 25, 2011 6:06 am | |

| OOoh! gosh-golly -- the power you have Mike!! | |

|

| |

Ned

Number of posts : 260

Localisation : Rayleigh Essex

Registration date : 2007-01-11

|  Subject: Re: Gearbox Nasties... Subject: Re: Gearbox Nasties...  Thu May 26, 2011 9:59 am Thu May 26, 2011 9:59 am | |

| - john bass wrote:

- OOoh! gosh-golly -- the power you have Mike!!

Naa these young whippersnappers want to drop the clutch and let the engine to do all the work for them. Not like in our day John when we had to do a Linford Christie before dropping the clutch.  | |

|

| |

Trevor Amos

Number of posts : 940

Registration date : 2010-08-13

|  Subject: Re: Gearbox Nasties... Subject: Re: Gearbox Nasties...  Thu May 26, 2011 7:28 pm Thu May 26, 2011 7:28 pm | |

| Hi, Mike,

Good heavens ! Thats a first for me, there must have been considerable torsional loadings in there to screw that

shaft in two ! Reminds me of the fate that befell a friend a way back. He was thrashing his Bultaco down the Norwich

Straight when the piston seized and locked the engine solid . There was such energy stored in the large dia, external

flywheel of the ignition system that it just kept rotating and screwed the crank mainshaft clean in two, taking the casings

with it! With energy levels of that magnitude available in a rotating body , it`s small wonder that the F1 boys embrace

KERS so enthusiasticly .

Any causal diagnosis yet ?

Ride safely, Trevor | |

|

| |

john bass

Number of posts : 1748

Age : 95

Localisation : Bensberg, Germany

Registration date : 2006-12-06

|  Subject: Diagnosis... Subject: Diagnosis...  Thu May 26, 2011 9:29 pm Thu May 26, 2011 9:29 pm | |

| Sounds daft -- BENDING?

...

Should NOT be in a layshaft -- or might it? | |

|

| |

john bass

Number of posts : 1748

Age : 95

Localisation : Bensberg, Germany

Registration date : 2006-12-06

|  Subject: PS... Subject: PS...  Thu May 26, 2011 9:39 pm Thu May 26, 2011 9:39 pm | |

| A good look at the gear teeth might tell something, like repeated excessive loading/unloading -- like a pair of gears running `tight the loose´ and bending the shaft repeatedly to induce a tensile stress into the surface of the shaft at various points around the shaft. Looks to me like cracks started at the surface and progressed inwards ....

Hhhhmmmm?? | |

|

| |

john bass

Number of posts : 1748

Age : 95

Localisation : Bensberg, Germany

Registration date : 2006-12-06

|  Subject: PPS... Subject: PPS...  Thu May 26, 2011 9:42 pm Thu May 26, 2011 9:42 pm | |

| Looks like the cracks started at the end of the splines... | |

|

| |

john bass

Number of posts : 1748

Age : 95

Localisation : Bensberg, Germany

Registration date : 2006-12-06

|  Subject: Again another PS... Subject: Again another PS...  Thu May 26, 2011 10:46 pm Thu May 26, 2011 10:46 pm | |

| Looks as if the ends of the splines were undercut into the radius of the shaft sufficient to make for a "notch" effect which with slight bending of the shaft or torsional shocks would start a crack forming at each spline end -- eventually cracking towards the centre... Doesn´t need much of an undercut to start a "Notch" effect... | |

|

| |

john bass

Number of posts : 1748

Age : 95

Localisation : Bensberg, Germany

Registration date : 2006-12-06

|  Subject: Yet Again... Subject: Yet Again...  Fri May 27, 2011 3:42 am Fri May 27, 2011 3:42 am | |

| Mike!

At the fracture face -- was the centre recessed?

or were there furrow lines across the surface starting from one edge and going across in parallel lines?

...

As I look at the picture it seems to me that cracks formed from each of the 5 spline ends -- and if the centre (of the fracture face) IS recessed -- it could be the "notch" effect (caused by an undercut where the spline meets the shaft surface) which means there was bending-stress concentration at each of these points to initiate initial cracking which just gets progressive in fatigue failure to destruction.

Maybe I am wrong?

Cheers!

John. | |

|

| |

john bass

Number of posts : 1748

Age : 95

Localisation : Bensberg, Germany

Registration date : 2006-12-06

|  Subject: Torsion or Rotating-Bending stresses or combination of the t Subject: Torsion or Rotating-Bending stresses or combination of the t  Sat May 28, 2011 4:23 am Sat May 28, 2011 4:23 am | |

| Can´t leave this alone.

In some IMechE publications I looked up some shaft failures and found the closest pictures to Mike´s layshaft picture were said to be "torsion fatigure stress failure..." AND "Rotating-Bending fatigue stress failure... -- not too much difference in appearance of either... both looking similar to Mike´s picture...

...

One important comment was that "...sudden changes of shaft diameter can act in the manner of the "Notch effect" in that the notch presents a high stress concentration at that corner where a radius would reduce the stress concentration. That a square cut corner is bad in repect of both torsion-loading and bending of the shaft.

...

Why I mention this is in relation to Mike´s layshaft is because the cracks seem to have started at the bottom-end corner of each spline, to then extend inwards.

Bending of a very stiff shaft would be caused by the connected gears -- trying to push each other apart. The actual amount of physical bending is very small but the Bending stress at an undercut, notch or sudden change -- without chamfer .. can be very large and plenty enough to initiate a crack.

...

Of course it could be a combination of both stresses, torsion & bending.

If torsion then the blame could be attributed to the higher performance of racing Bantams as versus original Post Office Bantam engine´s output performance.

...

With the curent racing Bantams now producing more power at higher revs it could be that gearbox components were underdesigned for the current load duty with rotating-bending-pulsing frequency.

...

Not to panic just yet -- this Layshaft failure of Mike´s might be a one-off.

...

Most important is to check the shaft´s vintage and to see if there is some indication for the reason for cracks to start.

...

I wonder now if others are going to have their gearbox shafts crack detected -- OR just TAKE A CHANCE?

...

Reminds me of my grass track days with a JAP Speedway engine that had an alloy con-rod. Crack detection of the rod after every meeting was necessary because they were known to break and if that happened about the only things to survive

would be the head and barrel ...

Not quite the same witha Bantam layshaft as Mike has shown.... | |

|

| |

mjpowell

Number of posts : 1074

Localisation : Lincoln England

Registration date : 2006-12-09

|  Subject: Re: Gearbox Nasties... Subject: Re: Gearbox Nasties...  Sat May 28, 2011 7:11 am Sat May 28, 2011 7:11 am | |

| Thanks for the input John...

I will have to do some head scratching??? | |

|

| |

Derek

Number of posts : 1065

Age : 63

Localisation : worcestershire

Registration date : 2007-06-15

|  Subject: Re: Gearbox Nasties... Subject: Re: Gearbox Nasties...  Sun May 29, 2011 3:14 am Sun May 29, 2011 3:14 am | |

| I have to say this is quite a simple one really, I like Johns explanations though, a little old hat,

This layshaft is clearly defective, and would have been prior to it doing this, there are very little loads on a layshaft well in comparison to the crank in this area with a large fly wheel, especially at this pont in the box, the gear teeth are the week points. not here, and would go much earlier under tortional twisting loads, so "No" do not agree -

My theory is "this is just what we call a catstrophic failure of the manufacturing process" 1-1000 products - for this type of process will have ? issues - BSA produced 8,000 close boxes, so there are another eight out there "somewhere". ?

Trevor my friend "yes" you are right """""" all the F1 guys are terified Of K.E.R.S.

No question about it, but its here to stay - Dad has been considering making one for the front or back wheel, much smaller but he has estimated even on our bikes it should give an extra 25BHP comming out of corners for short bursts.

mind you the weight is only 40kg, it will require the rear hub which must be used for the regs to be modified !

For the time being Im keepng my fingers crossed, and have alrady entered and so looking forwrd, to be back out at Cadwell !

"now I have recovered from that major operation",

I'm looking forwrds to ruffling a few feathers, James ? .

regards Derek | |

|

| |

john bass

Number of posts : 1748

Age : 95

Localisation : Bensberg, Germany

Registration date : 2006-12-06

|  Subject: Layshaft Subject: Layshaft  Sun May 29, 2011 4:06 am Sun May 29, 2011 4:06 am | |

| Fair comment Derek!

I would like to hear more from Mike though. How this fracture looks. How a normal layshaft looks? A picture would be appreciated showing the ends of the splines at the shaft surface.

| |

|

| |

mjpowell

Number of posts : 1074

Localisation : Lincoln England

Registration date : 2006-12-09

|  Subject: Re: Gearbox Nasties... Subject: Re: Gearbox Nasties...  Sun May 29, 2011 4:41 am Sun May 29, 2011 4:41 am | |

| Thats quite surprising Derek as that Layshaft has be in the bike post Elvington 2003 meeting.

So thats 8!! seasons with a defective layshaft..... Amazing..

I think I need to mileage layshafts to say 3'000 miles then put them in a 'used' drawer...

Will post more pic's John - Monday-ish.....

| |

|

| |

Derek

Number of posts : 1065

Age : 63

Localisation : worcestershire

Registration date : 2007-06-15

|  Subject: Re: Gearbox Nasties... Subject: Re: Gearbox Nasties...  Sun May 29, 2011 10:08 am Sun May 29, 2011 10:08 am | |

| I DID A GREAT REPLY TO THIS LOADS OF WORDS BUT NOW TO TIRED TO REPEAT IT FOR SOME REASON IT NEVERE POSTED ? O WELL

BUT IT WAS ABOUT TAKING THE P'SSS OUT OF MILAGING A LAYSHAFT. | |

|

| |

john bass

Number of posts : 1748

Age : 95

Localisation : Bensberg, Germany

Registration date : 2006-12-06

|  Subject: Quotation for you ... Subject: Quotation for you ...  Sun May 29, 2011 5:57 pm Sun May 29, 2011 5:57 pm | |

| For the want of a nail the shoe was lost, for the want of a shoe the horse was lost -- for the want of a horse the battle was lost --- etc ...etc...

First Layshaft failure I ever heard of (and saw, Thanks MIke!) -- layshafts never break -- not in those old machines which had Reserve Factors as high as ten on their designs.

Oh words word words -- I just love words when nicely put together -- it was an American Civil War General who said that bit above. He was probably drunk out of his silly military mind at the time -- writing because his mistress was fast asleeep.

...

Mike lost 25 points because his layshaft broke but take heart Mike, Peter is doing his usual thing of not attending a meeting and Ian has broken down too so chin up lad! just remember, next time out..., to pack a couple of layshafts in your old kit bag and smile, smile smile!

...-

Perhaps I ought to FOff -- disturbing your peace of a Sunday!

...

Cheers!

PS -- don´t forget that the force of gravity is really a good thing `cos if we didn´t have it, all our things, if not tied down, would be floating about and the lot from the Eastern Centre would be nicking them.

Particularly layshafts -- NOW! | |

|

| |

Edward Pickering

Number of posts : 739

Age : 47

Localisation : Gloucester

Registration date : 2007-02-19

|  Subject: Re: Gearbox Nasties... Subject: Re: Gearbox Nasties...  Sun May 29, 2011 7:25 pm Sun May 29, 2011 7:25 pm | |

| O dear / John you going to reply to this cause i'm going to give my 2 pence worth. Milage shafts ? This is never correct (only) eight seasons, well not sure how to enlighten you on this one, I probably can not spell the words correctly, but I going to try, this could be down to many things, guessing is not one of them, Milaging a layshft on a bantam ! sounds a little OTT - when you milage something its genreally done an the basis of wear levels especially on rotational objects, - your saying 300 miles because of fatigue??, I only Know of helicoptor rotor shafts that are milaged due to stress/fatigue - The failure on this layshaft is nothing to do with this, its either (i'm guessing) an inclusion or hardening issue, or a stress fracture as a result of ether of the forementioned, that has propogated into it cracking and sherring off, the loads are phenominal in the box admittedly, but not here, the teeth load is far higher, a crack caused do to the excesive backlash in the box? is likley?, but then it would not go here?, so either its a fauilty part that has in my opinion done more than 8 seasons racing or there is a fault with the material or hardening process -propgated on the shaft. my guess is there has been an inclusion or foreign body in the materials - often the case, I could be wrong and maybe it has taken 8 seasoon of racing to work through, but I'm sceptical, anyway I'm onlly guessing. ? you could well be correct and milaging in this case on a layshaft is a good idea!. As you have won 14 championships and many races but me I have only won a few times, and never won the main one. "forgive me I've had a good night out, and you know I can never rezist an oportunity to wind someone up." Regards Derek I think you had too much lemonade in your shandy last night Derek......................  | |

|

| |

Derek

Number of posts : 1065

Age : 63

Localisation : worcestershire

Registration date : 2007-06-15

|  Subject: Re: Gearbox Nasties... Subject: Re: Gearbox Nasties...  Sun May 29, 2011 8:32 pm Sun May 29, 2011 8:32 pm | |

| Hi did i send this to you blimey I thought Ihad lost it, anyway great thanks for posting it - ???

lemonade NO NO coloured water actually?

regards Derek | |

|

| |

Edward Pickering

Number of posts : 739

Age : 47

Localisation : Gloucester

Registration date : 2007-02-19

|  Subject: Re: Gearbox Nasties... Subject: Re: Gearbox Nasties...  Sun May 29, 2011 8:34 pm Sun May 29, 2011 8:34 pm | |

| Morning Derek,

No i found it in another post so copied it over for you.

Eddie | |

|

| |

john bass

Number of posts : 1748

Age : 95

Localisation : Bensberg, Germany

Registration date : 2006-12-06

|  Subject: Misquote?? Subject: Misquote??  Sun May 29, 2011 10:38 pm Sun May 29, 2011 10:38 pm | |

| Hi Ed!

I think I am being misquoted -- I never said owt about milaging a layshaft, or 300 miles or 8 seasons.

My interest was in comments made. Mike said -- I think Mike said -- the things apertaining to the above ...

History of any failed part is important if one wishes to determine the cause of a failure.

...

I got the impression --maybe wrongly -- that the conclusion was "One-off failure -- just carry a spare..."

...

Fatigue failure is only related to the time of a component´s life in its actual number of reversals of cyclic stress:-- load/unload, over-load/ no-load and OverStress/ZeroStress reversals. CAN BE TWO HOURS OF CONTINUOUS OPERATION or even several years to failure...

...

... We could therefore take Miké´s comment, of crankshaft weight being attributable, a little more seriously.

We would have to count the numberr of times he whacks the throttle open per lap, per race, per race meeting -- ad infintum!

...

What I said was something very Old Hat -- and exceedingly stupid -- that a layshaft could possibly break because of an undercut, sharp change of contour -- or something bad in manufacture or heat treatment -- and capped that by mentioning BENDING.

BENDING?? ridiculous!! Short stiff shaft cannot bend! -- Ah! but it can be subject to rotating-bending stress which when acting on a small notch can become a crippling, alternating, overload/no-load stress that iniates a crack.

...

Major learning in Fault Finding -- for me -- was "Finding a distinction" -- a diffrence in a mechanical system that has never failed in thousands of units and thousands of hours of operation -- suddenly fails.

...

Just discovered such a distinction. Fromthe NORMAL layshaft configuarion, that is -- five small bolts holding a plate which contains a ball-bearing for the layshaft...

????

Laughable statement, JayBee! -- go into the corner and put on your dunce´s hat!

...

But please!

This is the very first layshaft failure I have known/seen and it has two distinctions so far. These are are "heavy fist/crankshaft Mike" and a "different bearing used on the layshaft".

..

I am all for cancelling out the first of those and scoffing at the second -- but I await another picture before doing so.

...

Humble apologies for taking so long...

| |

|

| |

Edward Pickering

Number of posts : 739

Age : 47

Localisation : Gloucester

Registration date : 2007-02-19

|  Subject: Re: Gearbox Nasties... Subject: Re: Gearbox Nasties...  Sun May 29, 2011 10:53 pm Sun May 29, 2011 10:53 pm | |

| Hi John,

what i posted is what derek had written but was in a different topic by accident so i copied it over for him but maybe i should of quote copied it. The layshaft mileage and 300 miles and 8 seasons is between derek and mike replies on this topic.

Hope that makes sense.

Eddie | |

|

| |

john bass

Number of posts : 1748

Age : 95

Localisation : Bensberg, Germany

Registration date : 2006-12-06

|  Subject: Nasty Gearboxes Subject: Nasty Gearboxes  Mon May 30, 2011 2:11 am Mon May 30, 2011 2:11 am | |

| No need of apology Ed...

This layshaft one if of great interst to me -- since, as I said -- I´d never heard of a layshaft failing:- there should be no reason for such a rarity but common-sense tells us that there may have been many -- we just haven´t got to know about them.

As you are obviously aware some automobile components are mileaged in that they are expected to wear out after a set time or mileage e.g a vee-belt or chain... -- but a gearbox shaft ought to last the life of the engine...

I´ll leave it alone for a bit -- people must be getting bored with it -- but I cannot drop it altogether.

Cheers!

JayBee.

| |

|

| |

Derek

Number of posts : 1065

Age : 63

Localisation : worcestershire

Registration date : 2007-06-15

|  Subject: Re: Gearbox Nasties... Subject: Re: Gearbox Nasties...  Mon May 30, 2011 5:29 am Mon May 30, 2011 5:29 am | |

| Hi john

Sadly some of the greatest Engineers from this country have come and gone, you should not take my saying old hat as an insult, I put you in the same mould as people who I could listen too. usually to go to sleep LOL.

Look at the plane Concord, ! do you know it was - de tuned, if this is the correct word, and could actually fly 3x its passenger carrying speed, in fact it is said it actually went into space during trials, well before the shuttle did, they still can not get near to its performance, the only thing they built, that could get near it, leaked on the ground from lots of places, they had to fly it to save face, but every time they did, when it took off, they had an army of fire fighters on emergency, at the ends of the runways, and it could not carry passengers, so why did Concord get scrapped, noise -? no- inefficient fuel -? No "The Americans" and we had another called the TSR2, there is still one left ? they only found it recently, the americans had an agreement with the government at the time, who as usually were week, and agreed with such demands to scrap it and all the tooling ? why all the tooling ? for the same reason all the tooling for Concord was scrapped? the TSR2, ? Well thats the story - But thats another world altogether.!

I was once quoted "if it looks right "it usually is.

so while we are babbling on about this layshaft, lets get back to reality, why did it brake, "I don't know why - we will never really know, "IS MY GUESS" we can only summarise on our experience, and life of knowledge.

I have to say inclusions in the metal, a fault, because of a previous experience, but even the strongest, microscope or illuminum Xray's, will not tell you, we still have to guess. ? so like I said "I could be wrong".

Mike can you send john the broken parts, I will pay for the postage, I believe he lives in germany/ or canada - send it recorded delivery John can you PM mike your address, send me the receipt,I WILL GIVE YOU THE DOSH AT CADWEL. lets move on to something more interesting, like making our bikes go forwards and faster.

"Important note John needs both ends of the broken shaft, so lets put him out of his misery and an end to this topic.

best Derek

| |

|

| |

john bass

Number of posts : 1748

Age : 95

Localisation : Bensberg, Germany

Registration date : 2006-12-06

|  Subject: Thanks Derek... Subject: Thanks Derek...  Mon May 30, 2011 9:27 pm Mon May 30, 2011 9:27 pm | |

| Thanks Derek -- for those kind words,

No need to send any parts -- all I need are a couple more pictures and Mike to answer a couple of questions and I am faily sure NOW I know why the layshaft broke -- OK! I am only guessing too, and I´ll tell you why:-

...

Long ago, in the dim and distant past, Mr Ford paid me handsomely to take engine components and smash and break them. I had to design rigs that would run for thousands of hours or only ten minutes to break those components and surprisingly, often after hours of boredom waiting for the failure to happen there´d be a might bang! and I´d wake myself up to go and see ... It was called Accelerated Fatigue Testing. And was I fatigued. Bored! Yawn! I´d right my report and state my opinion but the fracas would not stop there -- there´d be all Automotive Engineering areas of UK alerted -- and other opinions would be bandied about -- so -- you see -- there are always lots of opinions WHY ...

Particularly when it came to failed half-shafts in rear axles...

Years later I exploded diesel flywheels by overspeeding them -- great fun ...

You were right -- it could have been a defective part and Mike asks, if so! why didn´t it not break earlier and the answer to that is, it was a fatigue failure NO DOUBT about that and an undercut (groove or sharp corner) in the shaft surface could have initiated a fatigue crack.

I reckon Mike could race with that replacement shaft for 4 years before crack- detecting it -- without too much fear of failure. but I am not sticking my neck out to state that --

MIKE! as soon as you split the crankcases crack-detect that replacement shaft.

The question then arises was it torsion load or some other stress that caused the crack?

Which has us looking for distinctions -- that is differences from the norm -- from all those layshafts that have been subjected to the same service operation Mike has been giving it without any others than that of Mike´s one failing.

The first immediate distinction is that layshafts in modern Racing Bantams are subject to massive overloadings (3 to 4 times the power) comparedw ith Post Offic Bantams -- vicous `full elbow´ acceleration (of Heavy Crankshafts??) of drive components but then we know that the designers of those earlier days would always use a reserve factor of much more than 3 or 4 times the expected shock-loading and as you said, Derek, the gear teeth would surely have broken first if overloading were the case...

So! why should a very strong shaft break before the gear teeth snapped off?

Further distinctions are necessary....??

Cheers!

JayBee sitting on his Old Hat!

| |

|

| |

mjpowell

Number of posts : 1074

Localisation : Lincoln England

Registration date : 2006-12-09

|  Subject: Re: Gearbox Nasties... Subject: Re: Gearbox Nasties...  Mon May 30, 2011 10:38 pm Mon May 30, 2011 10:38 pm | |

| .... and another thing... it was an early D1,3 layshaft with the extra small dogs and hollow sliding gear, so less length to distribute torsional loading!? John- left gearshaft(s) at work so will be another week before any pic's.... sorry My thoughts are :- run a layshaft for 2 seasons then replace, giving used layshafts to the compertition!!  And what about changes in output pair would running 26/21 instead of 24/23 have much of an effect?? John ?? | |

|

| |

Sponsored content

|  Subject: Re: Gearbox Nasties... Subject: Re: Gearbox Nasties...  | |

| |

|

| |

| | Gearbox Nasties... |  |

|