|

| | And quiet flows the duct ! |  |

| | |

| Author | Message |

|---|

Edward Pickering

Number of posts : 739

Age : 47

Localisation : Gloucester

Registration date : 2007-02-19

|  Subject: Re: And quiet flows the duct ! Subject: Re: And quiet flows the duct !  Fri Oct 05, 2012 11:24 pm Fri Oct 05, 2012 11:24 pm | |

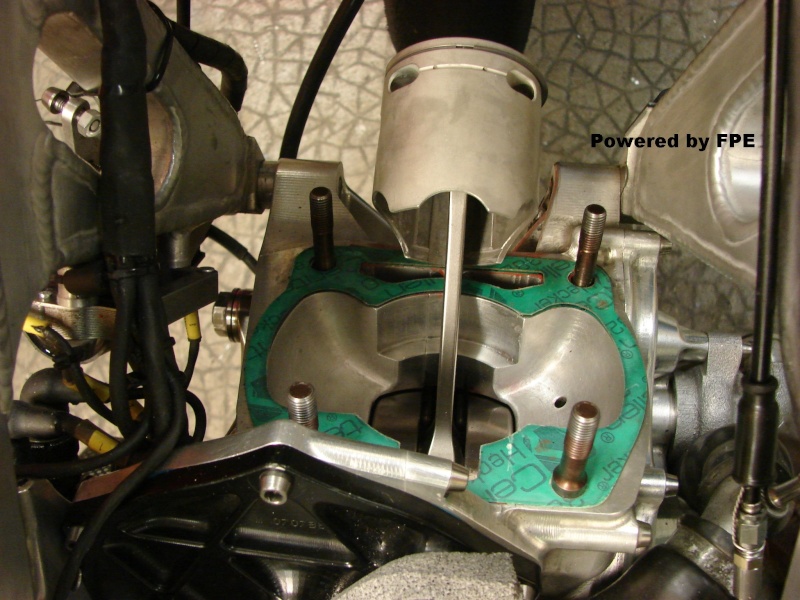

| Courtesy & Property Of Trevor Amos.  | |

|   | | john bass

Number of posts : 1748

Age : 95

Localisation : Bensberg, Germany

Registration date : 2006-12-06

|  Subject: Corrected readings -- of course!! Subject: Corrected readings -- of course!!  Fri Oct 05, 2012 11:42 pm Fri Oct 05, 2012 11:42 pm | |

| Corrected readings -- of course!?

Doesn´t really matter -- I suppose -- because the torque is 7.5% down and when correcting to whichever Norm/Standard our maximum correction used, was 4% ...

...but just a moment John-Boy!? If we had corrected by 4% (thunderstorms and all that sort of thing) mightn´t there have also been an error in measurement somewhere -- to account for the difference -- the machining looks so - oh - so good ...?

BUT!

There were two changes at one time? Weren´t there? As I read it: The exhaust timing and the bigger transfer entry mods were done at the same time...??

I have seen a bumpy torque curve developed by a simple pip formed in the intake port of a 4-stroke motor -- but that was a 4 stroker... Apparently speeded up the air-charge just before the valve...

Never make two changes at the same time when trying to develope more torque or power on the dyno -- that´s what I was told about 65 years ago ...

Opening up the entry slowed down the charge --- er, did it?

Cheers! | |

|   | | Trevor Amos

Number of posts : 940

Registration date : 2010-08-13

|  Subject: Re: And quiet flows the duct ! Subject: Re: And quiet flows the duct !  Sat Oct 06, 2012 12:52 am Sat Oct 06, 2012 12:52 am | |

| Thankyou for the picture Ed ,

I`ve been trawling around for a suitable picture to illustrate how important it is to have a smooth , rounded entry to the transfer duct , this is the best i`ve yet to find .

The actual barrel is an early Aprilia clone , they all are these days !

Crucially , if flow can attatch to the inner radius , the Coanda effect , and remain there through out it`s entire length , and , be persuaded to attatch to the piston crown during the whole transfer phase , then heaps of gas flows and the piston crown is cooled for free ! A sharp duct entry edge here will immediately detatch flow and the whole event mushes to high turbulence and poor performance .

I think anyone studying this pic will know instinctively , of the inherent correctness and efficiency of the illustrated flow regime .

Catch you all later , Trevor | |

|   | | Trevor Amos

Number of posts : 940

Registration date : 2010-08-13

|  Subject: Re: And quiet flows the duct ! Subject: Re: And quiet flows the duct !  Fri Oct 26, 2012 8:52 pm Fri Oct 26, 2012 8:52 pm | |

| Over the duration of this post topic i`ve had a couple of PMs asking where the floor of the transfer port should be at piston BDC ? To maintain the full effect and benefit of the Coanda phenomenon then the piston edge and lower port edge must be coincident , and , depending on individual piston crown radius the whole duct

inner wall and crown should form a stepless , flowing curve , almost balletic in grace !

Afterall , the duct is at it`s most turbulent free , and least energy absorbing , state at bdc , and if your pipe is working for you and the collective port efflux angles

are optimised , then the cylinder can be purged of unwanted residuals and lovely clean combustable gas remains . It never , ever works that way but that`s no reason

not to try ?

The real down side to this is that big " sand bunker " of a trap to the unwary , the exhaust port , and the more area of the cylinder that occupies , without the redeeming influence of a power valve , the greater the short circuiting of good gas occurs , and the bottom drops out of power band !

| |

|   | | john bass

Number of posts : 1748

Age : 95

Localisation : Bensberg, Germany

Registration date : 2006-12-06

|  Subject: Coandâ Effect... Subject: Coandâ Effect...  Fri Oct 26, 2012 10:55 pm Fri Oct 26, 2012 10:55 pm | |

| All good stuff Trevor!

What about the heating effect of the induced air charge being in contact with warmer surfaces as it travels thro´the crankcase and up the transfers with its pressure increasing -- by crankcase compression??

Silly question! Just trying to get a handle on gas flow reality at about half-a-century too late!

Cheers!

JayBee. | |

|   | | Trevor Amos

Number of posts : 940

Registration date : 2010-08-13

|  Subject: Re: And quiet flows the duct ! Subject: Re: And quiet flows the duct !  Sun Oct 28, 2012 3:10 am Sun Oct 28, 2012 3:10 am | |

| Certainly not a silly question John , inlet charge temperature goes to the heart of the thermodynamic considerations of all engines , both two and four stroke .

From starting at around 20*c at the carb bell mouth then being compressed to over 200*c prior to ignition , any unwanted temperature gain can get very serious .

Reverse flow from cylinder to crankcase will ramp up temps pretty rapidly and in extreme cases auto ignition and detto can set in , and the engine won`t like that for long . Hot charge is far less dense than cold and will be power deficient at the outset , to this end it is important to ensure that plenty of cool air gets to the carb

that sits behind a hot engine and /or radiator and behind an all enclosing fairing .

Excessive valve overlap at exteme timings with the 4t engines can lead to back flow of exhaust gas that contaminates and raises the temps which lead to mysterious power loss and even deto , and all because of elevation of inlet charge temp.

In short , if the initial air/fuel mix is hot , then power delivery goes down hill from then on , and if petrol begins to vapourise early , the remaining mix will combust

poorly , and so the cycle continues ad infinitum !

Trevor

| |

|   | | john bass

Number of posts : 1748

Age : 95

Localisation : Bensberg, Germany

Registration date : 2006-12-06

|  Subject: Thanks Trevor! Subject: Thanks Trevor!  Mon Oct 29, 2012 3:12 am Mon Oct 29, 2012 3:12 am | |

| Thanks Trevor! I was thinking of the possibility of intercooling the air-charge as it progresses up the transfers...??

Another daft idea????????

Cheers! | |

|   | | Edward Pickering

Number of posts : 739

Age : 47

Localisation : Gloucester

Registration date : 2007-02-19

| |   | | Trevor Amos

Number of posts : 940

Registration date : 2010-08-13

|  Subject: Re: And quiet flows the duct ! Subject: Re: And quiet flows the duct !  Thu Nov 01, 2012 1:21 am Thu Nov 01, 2012 1:21 am | |

| No , it`s not an exhibit lifted from Tate Modern , but casting cores to produce an Aprilia clone cylinder , and of course it`s upside down !

I`ve posted it to illustrate the duct passages from the inside out perspective , the nice flowing curves of the A and B ducts can clearly be appreciated and is what Bantam engines should aspire to replicate ! That is easy to say and damn tricky to actually do , and whist my early effort falls short of this , it goes some way along the road to a more efficient system .

The actual engine to which this belongs is a karting version of the old Rotax 250 that predated the vee job , karts don`t have installation headaches as bikes do .

Again , our thanks must go to the ever dependable Ed !

Enjoy !! ? Trevor

| |

|   | | john bass

Number of posts : 1748

Age : 95

Localisation : Bensberg, Germany

Registration date : 2006-12-06

|  Subject: Wünderbar! Subject: Wünderbar!  Thu Nov 01, 2012 10:28 pm Thu Nov 01, 2012 10:28 pm | |

| Wünderbar Trevor!

In the year 5012 an archeoligist will make an amazing discovery and annouce to the world that the earlier versions of mankind not only "...bowed down to effigies they made in wood & stone ..." they also sculptured the results of their experiments undertaken with animals...!! or the creatures that dropped in from Mars...

Well done that man.

Cheers!

JayBee -- for John-Boy.

PS -- a day later, when I´d found and got on my proper reading-specs: Top picture: Bloke in the middle reminds me of a well-known Bantam racer -- Right now, I can´t think of his name just now -- often had his head turned to the right when approaching a hairpin-- hmmm! whom can it be? Had his elbows stuck out just like in that picture ... Skinny bloke with a large cranium - was a fleaweight -- small wonder he won a lot of Bantam races... I´ll give it some thought and get back to you....

Cheers!

JayBee -- | |

|   | | john bass

Number of posts : 1748

Age : 95

Localisation : Bensberg, Germany

Registration date : 2006-12-06

|  Subject: Fascinating!! Subject: Fascinating!!  Mon Nov 05, 2012 5:26 pm Mon Nov 05, 2012 5:26 pm | |

| Fascinating!!

I could look at them for hours............... | |

|   | | john bass

Number of posts : 1748

Age : 95

Localisation : Bensberg, Germany

Registration date : 2006-12-06

|  Subject: Wake up! This is exciting...!! Subject: Wake up! This is exciting...!!  Mon Nov 05, 2012 11:40 pm Mon Nov 05, 2012 11:40 pm | |

| Schnarhsch -- schnarsch -- schnarh...

That´s me snoring in Deutsches lingo. Are you all sleeping there below?

Quietly flows the duct is not strictly accurate.

We were living in Beccles Drive Barking, having moved from Cavendish Gardens, Barking to Churchgate (No! I hadn´t become a vicar...) Cheshunt and back to Barking. Having just got my engine for Icarus-1 back from Derek I was keen to make sure it functioned. I should not have had any doubts -- Derek always made sure the engine was extremely reliable. The only real trouble we ever had with Icarus-1 motor was partial piston seizures which was my responsibilty anyway... At the bottom of our Beccles Drive lawn was a footpath, so at around 06.00 -- one morning in summer of 1972 -- I ran and bumped... Engine fired up immediately. What a crackle! I´d say "noisilly fired the duct" -- with such a staccato rattle from the pipe it really sent a spinetingling shiver thro´every part of my hard-worned body. Being a narrow foot path I couldn´t turn round . In such a posh neighbourhood where everyone watches her/his neighbours for financially-depreciating their property by having a single weed in the garden I´d surely be in the smelly stuff with them ....

What a difficulty it is? Turning a Bantam racer around -- thro´ 180°, I mean? So it is burnt into memory that I did not want to stop the engine but I wanted to get back to my garden shed as quickly as possible.

I did -- with few blips of wonderful, crackling sound from the exhaust pipe...

Only three people complained: the family! Waking them so early!They reckoned I should have been locked up.

What made it sound so different? I reckon it was the cold morning air ....?

...quietly flows the duct indeed??!!

Yaaaawwnnnn! & Cheers!

JayBee. | |

|   | | Trevor Amos

Number of posts : 940

Registration date : 2010-08-13

|  Subject: Re: And quiet flows the duct ! Subject: Re: And quiet flows the duct !  Tue Nov 13, 2012 7:15 am Tue Nov 13, 2012 7:15 am | |

| So there you are in the car , sitting waiting for the traffic lights to change from red to green , as they do so the lead car moves off , and , being fifth in the queue you move ten seconds later and the whole traffic column gets into motion and moves away . your car goes from being inert to to having dynamic motion and the direction it travels in is determined by the road layout !

This little scenario is a good analogy to what is happenining in our transfer ducts . Just prior to port opening , the gas column is effectively inert , and it is only pressure differentials , created within the working cycle of the whole engine , that will get that column moving into the cylinder in the time frame you have designed in , and that needs a specific flow velocity ! The whole mass of a gas column in a duct can be described as , specific mass x duct length x c/sec area .

In turn , velocity is inversely proportional to duct c/s area , and the pressure differential required is proportional to the square of that velocity ! And i always thought it was just a passage from there to somewhere else !!

Looking at that equation it is easy to appreciate the huge number of permutations available in establishing sensible numbers , but calcs can be one thing and realism and experience another ?!

However , getting back to our inert gas column , at the port/cylinder boundry the gas moves quickly in response to negative and positive pressures and is followed progressively by the remaining gas , and the crankcase replenishes that moving mass . If the engine engine pumps and sucks with more vigor and efficiency than the

competition , you`ll make more power ! Always assuming , of course , that your predatory exhaust system doesn`t devour all of the good stuff and leave the combustion cycle with nowt to play with !

There are stacks of caveats to the events illustrated , but a lot can be relegated to the side lines by the limits imposed on the original Bantam engine , the principle being the 3 speed gear box .

A big and/or long duct , upon port opening , will resist acceleration , need a lot of energy to initiate movement and take a long time to achieve a meaningfull velocity ,

At low rpm that will be a disadvantage and lead to a reduced power band width , the potential for high bulk flow will be there but will only be available at higher rpm .

What you don`t ever want to be doing , in our homemade engines , is always trying to make up for that , which was missing in the design stage !

| |

|   | | john bass

Number of posts : 1748

Age : 95

Localisation : Bensberg, Germany

Registration date : 2006-12-06

|  Subject: Wot about being on your bike...? Subject: Wot about being on your bike...?  Tue Nov 13, 2012 6:53 pm Tue Nov 13, 2012 6:53 pm | |

| Wünderbar Trevor!

Now, what about being on your bike? -- alongside that car number-five in the car line-up by the traffic lights -- you sneak alongside, up to car number one and as the lights change you jump ahead and are then at the next traffic lights (they are not far apart!) before they change and hence leave car #5 way behind ....

In its analogy form that is legal cheating. A copper might get nasty about the cyclist being a danger...!!!

In this other (Bantam) form I have been dreaming up ways of CHEATING with the transfers but I ain´t going to tell ... because cheating ain´t fair -- so there!!

Yyyaaaawwwnnn!

4°c here with sunshine -- that´d make the exhaust crackle louder --- wouldn´t it?

Uppyerduct - Ducky!

Sorry! that´s terribly rude -- I shall delete .................. | |

|   | | Edward Pickering

Number of posts : 739

Age : 47

Localisation : Gloucester

Registration date : 2007-02-19

|  Subject: Re: And quiet flows the duct ! Subject: Re: And quiet flows the duct !  Tue Nov 13, 2012 8:16 pm Tue Nov 13, 2012 8:16 pm | |

| Courtesy & Property Of Trevor Amos  | |

|   | | Trevor Amos

Number of posts : 940

Registration date : 2010-08-13

|  Subject: Re: And quiet flows the duct ! Subject: Re: And quiet flows the duct !  Tue Nov 13, 2012 9:40 pm Tue Nov 13, 2012 9:40 pm | |

| The picture posted here is of course the Aprilia , as can be seen from the rear disc installation . The reason it`s here is to show how clean and smooth every feature is

, no sharp edges to trip up gas flow , generous corner radii in the transfer cutaways and lovely , curving blend from crank disc edge to barrel interface . You can just see that fluid flow is as unimpeded as is possible to attain and which will always make the power . It perhaps doesn`t need me to suggest that this level of attention to flow promotion is what we all should strive to achieve !

I am begining to wonder about the world you currently inhabit John , breaking the law on yer bike , cheating with a Bantam engine , but it makes a great image with you sprinting away from the lights , legs flailing away , head down , full of competitive intent , only to be carted away to the nearest lock up for being a danger to the public !!

We perhaps have to wonder about number 15 in the queue , for the lights could change before he`s away and therefore won`t contribute any gas to the barrel ?

Enjoy your day every one , Trevor | |

|   | | john bass

Number of posts : 1748

Age : 95

Localisation : Bensberg, Germany

Registration date : 2006-12-06

|  Subject: Fantastic! Subject: Fantastic!  Wed Nov 14, 2012 5:24 am Wed Nov 14, 2012 5:24 am | |

| Fantastic pic Trevor! Thanks!

Never cheated at any sport -- and what I have learnt on here is that I never really got into Bantam engine tuning. Like I said the engine was not my baliwick at the time and if I remember aright I didn´t do much with Icarus-2´s motor either. Wobbleyman did the ports and several people criticised Wobbles engine & bike prep... anyway. Actually, I had very little time to spare -- except for gettiing the leg over at Brands and meetings....

I did have an RE 125 -- my work-ride hack -- when working at Walthamstow Tech with which I did a `suck it & see´ experiment with the transfer ports which did make a distinct difference on the road and got me in bother with the Fuzz -- actually exceeded the speed limit in a 50mph area!! -- but any little improvement to RE 125s would surely show a difference. Bill Lomas´s comments about his Chief Engineer at RE are proof of that. There were two world-war-2 compensation DKWs at Enfield´s factory which Enfield´s management ignored and sent over to BSA -- with, as we all know, the birth of the Bantam....

Yyyaaawwwnnn -- oh! how terribly boring....!! | |

|   | | Edward Pickering

Number of posts : 739

Age : 47

Localisation : Gloucester

Registration date : 2007-02-19

|  Subject: Re: And quiet flows the duct ! Subject: Re: And quiet flows the duct !  Fri Feb 15, 2013 2:00 am Fri Feb 15, 2013 2:00 am | |

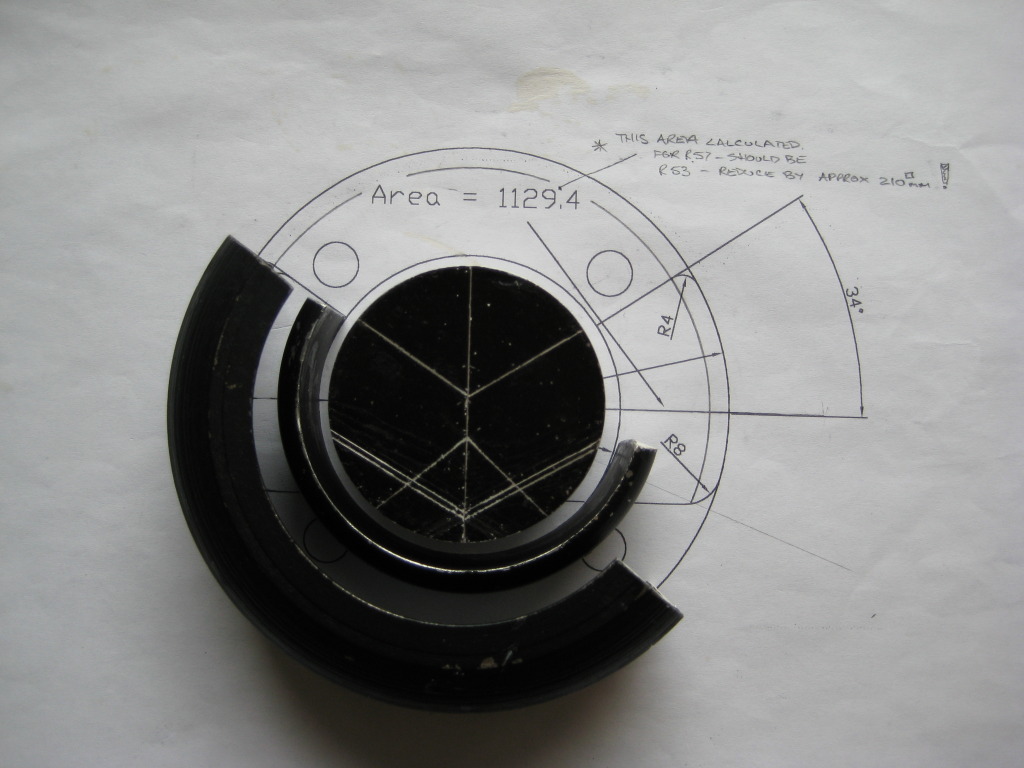

| Courtesy & Property Of Trevor Amos  | |

|   | | Trevor Amos

Number of posts : 940

Registration date : 2010-08-13

|  Subject: Re: And quiet flows the duct ! Subject: Re: And quiet flows the duct !  Fri Feb 15, 2013 2:21 am Fri Feb 15, 2013 2:21 am | |

| Many thanks for posting that up for me Ed !

Hi all ,

It was my original intention to include this image in the original post , but i could not find the ally billet with the radial lines inscribed on it . It came to light in a drawer marked Rods/ Bearings , so here it is now .

Bit pushed for time now but could incude a descriptive piece later ?

Cheers Trevor

| |

|   | | Trevor Amos

Number of posts : 940

Registration date : 2010-08-13

|  Subject: Re: And quiet flows the duct ! Subject: Re: And quiet flows the duct !  Sat Feb 16, 2013 12:27 am Sat Feb 16, 2013 12:27 am | |

| First to the ally block , i first used these back in the long stroke days of the 60s/70s , the idea being to check how the original cast ports matched up , their symmetry , and the differences were remarkable , and the flat top revealed miss matches in opening points . A short length of 1/4 square bar had the corners machined off in a lathe , for about 3/8ths long . the round part gave point contact in the outlet side of the port and the flat maintained stability whilst the angle was incised with a very fine point scriber along its length to the bore centre .

The under side is counter bored and tapped through the wall , and a small screw just nips the bore to hold things in place . What you see here is the outcome of just that exercise and graphically illustrates the accuracy that machining of ports in a liner can provide , but careful work by hand can easily replicate this if patience is shown !

But it has to be said , that perfect ports that are wrong angularly , dimentionaly and positionaly , still won`t make the power !

The radial lines shown , represent the 2007 spec and this is a progression from the 1997 spec and the 2012 is different again . Each time step represents a small progresion in engine performance , but not necessarily at peak power and rpm . The aim is to get bike and rider round the circuit in the shortest time possible and if that time is less than anyone else you win the race ! What i can`t show are the axial deployment of the progressive opening phases of the ports and their coreography in the gas stream column trajectory rising up the rear of the cylinder to the combustion chamber ! Efficient scavenging of the cylinder whilst retaining as much of the fresh , cool , charge as possible will always make the power . Or as one , pithy , comment i saw so succinctly phrased it , " get the s..t out , keep the sweet in , and rock and roll" !!

Catch you all later Trevor

| |

|   | | Trevor Amos

Number of posts : 940

Registration date : 2010-08-13

|  Subject: Re: And quiet flows the duct ! Subject: Re: And quiet flows the duct !  Fri Feb 22, 2013 4:38 am Fri Feb 22, 2013 4:38 am | |

| The list below shows the percentages , of the circumference of their bores , that transfer ports occupy in a number of known engines , and their individual performaces are established facts with the Aprilia the outstanding power producer !

Aprilia 54..................... 67.8

Honda 54.....................59

Bantam 54...................56

Todd186 62..................31.8

Bantam Snowy 64.........30.5

A couple of small anomolies need to be pointed out . On the Todd 186 the stroke is 62mm , and on the rubbing of Snowy`s` engine , from which that info was obtained ,

the ports are shown as arcs and not chords , a quick calc showed so little difference that i went with the published figures of 14 and 17 respectively , on all of the other engines , the port dimentions are chordal .

On the basis that there is never enough transfer port area to make the power , the 175 boys look a little in deficit ?

I know that one can make statistics mean a little or a lot depending on what is trying to be stated , but the above does seem to make a point .

Trevor | |

|   | | john bass

Number of posts : 1748

Age : 95

Localisation : Bensberg, Germany

Registration date : 2006-12-06

|  Subject: All huff & puff in the end... Subject: All huff & puff in the end...  Sun Feb 24, 2013 5:32 am Sun Feb 24, 2013 5:32 am | |

| Point was made Trevor. Impressive statistic but somehow I think Aprilia had a bit more up the sleeve. For one thing the Aprilia was/is not just piston-ported induction -- or is it?

Excuse me for being totally ignorant on the subject, I only get my up-to-date, two-stroke info from on here and with 4-stroke engines I always considered several contributing factors working together made up for the induction - exhaust sytem working well or just being huff and puff.

What are the other contributing factors to obtaining a good stuffing into the combustion chamber with Aprilia...?

Sorry to be a pain...!

Cheers!

JayBee for John-boy... | |

|   | | Trevor Amos

Number of posts : 940

Registration date : 2010-08-13

|  Subject: Re: And quiet flows the duct ! Subject: Re: And quiet flows the duct !  Mon Feb 25, 2013 3:49 am Mon Feb 25, 2013 3:49 am | |

| Hello John ,

Way back in 1955 ( or there abouts ) Joe Craig and his band of Norton men brought the level of the 500 Manx engine performance to a staggering 55bhp and the bmep value to an amazing 14 bar, and it did this at the modest rpm of just over 7,000 ! It took the four stroke motor cycle world , to see the advent of a small improvement to 15 bar , untill the multi cylinder engines of Moto GP and these were turning at 17,000 rpm .

The Norton men improved power in an incremental way , using inspired gueswork and scientific nous together with detailed work on the engine dyno and this was on a very limited budget and rubbish petrol with low octane rating .

So it was with the Italian , Aprilia engine , that a similar regime with a dedicated team were able to develop a machine that became unbeatable in its class with a level of sophistication unseen before in the" lowly " world of single cylinder 125 GP racing . In a inspired act of recruitment Jan Thiel and Frits Overmars were both engaged to develop the machine and this they did , achieving 55bhp at 13,500rpm at its final development stage . With Jan they had the leading technician in disc valve engines , and with Frits they had an ex racer who was , by profession , a Physisist , so with Jan`s engine designs and the fundamental thermodynamic and gas dynamic knowlege of Frits , power also went up in a logical and incremental way .

Answering your question of just how this was done , we can start at the begining , ie, the 42/43 mm diameter carb , much larger than the Norton , the inlet port is large and the duct is very short , and is opened very rapidly at the point most favourable to optimise case filling and again is closed at the point of most gas retention . With the massive transfer port area the cylinder sees a huge flow of fresh charge and with very clever , inteligent radial and axial flow control of the transfer column at the rear of the cylinder , old combustion residuals are effectively purged from the cylinder leaving very pure combustable gas behind. To facilitate extraction of the unwanted rubbish the exhaust port extends to about 170* of the cylinder circumference . whilst all of this is going on the exhaust system is orchestrating the magnitude and timing of the pressure cycles and serves to augment the natural breathing potential of the cylinder porting . Add in an effective , dual range ex port valve with it`s progressive opening , starting at 10,000rpm and fully open at 12,000 ! A very powerful , mult- mapped ignition system which controls the solenoid carb , anti detto system , exhaust outlet temperature signaling , and a lot more besides .

There are , of course , downsides to this performance level , the first being that below and above the effective power band the engine will not run any sense and works riders were admonished to never let revs drop below 10,000 and running on a part throttle will induce the onset of detto and the engine will self destruct in short order !

The combustion chamber runs at 15.5:1 and uses a part torroidal profile with favourable volume / surface area ratio and very short flame travel . The cooling system moves a lot of water around the head , cylinder and crankcase , thereby ensuring thermal stability, so crucial to reliably maitaining consistent power .

There is so much more to this incredible engine , which exercises it`s design brief to perfection , mind you i dread to think what all of this might have cost ?

Cheers for now , Trevor

| |

|   | | john bass

Number of posts : 1748

Age : 95

Localisation : Bensberg, Germany

Registration date : 2006-12-06

|  Subject: Thanks Trevor... Subject: Thanks Trevor...  Wed Feb 27, 2013 7:25 am Wed Feb 27, 2013 7:25 am | |

| Thanks Trevor,

I can visualise just how much such engine development cost. That is because the 4-stroke diesel engine I was involved in the development of -- in Canada -- had a Renentrant-Toroidal combustion bowl in the piston crown. The shape of this -- depth of throat, shape of bowl, with pip in the base, took up years of dyno development time at Portz, Cologne R&D before we got the engine to develope further in Canada. This engine´s cylinder head had side by side intake and exhaust ports which by the fact of being side-by-side had to be rectangular to obtain the necessary cross-section flow area. ... In Canada we developed the cross-flow head where the ports were round and on opposite sides of the head. Thus we were able produce a controlled amount of swirl because the intake port could be in its shape as part of a spiral -- which changed the performance drastically, fortunately for the better. With the ability to control swirl we could then make changes to the fuel-injection rate to get the optimum power/emissions....

We were able in laboratory controlled conditions to get the injection rate to be such that the initial high rate got the fire going -- as it were -- then a longer, lower than previous pressure rate for the rest of the injection period. To put it crudely instead of a rapid bump of combustion pressure we had a longer drawn out combustion period (at lower combustion) pressure which actaully gave more power than previously.ie It was a flatter bmep & torque curve ... l

The effect was similar to using a methanol fuel instead of petrol.

Since then I have often wondered if direct-injection of petrol in a two-stroke would improve matters in a similar manner. A positive lube system would be necessary that might nullify any gains....?

Cost, of course, another matter in R&D ....

Just added this PS -- it was an air-cooled diesel engine of V-8 configuration...

Cheers!

JayBee.

| |

|   | | Trevor Amos

Number of posts : 940

Registration date : 2010-08-13

|  Subject: Re: And quiet flows the duct ! Subject: Re: And quiet flows the duct !  Thu Mar 14, 2013 2:08 am Thu Mar 14, 2013 2:08 am | |

| Hello All ,

I suppose that just about every Bantam racer has , at some time or other , considered what the correct length could be for the inlet duct on their engine and as to how it could be calculated ? Exhaust systems are made using acoustic wave motion , with temperature and time as the primary factors , so why not the inlet ,and if you can arrive at an installation number and it gives a smidge more power , that`s great ?

With the transfer ports open the exhaust action pulls fresh mixture from the crankcase and , at some point after BDC , the case pressure goes sub-atmospheric , a suction wave goes all the way through the inlet duct /carb to the open air . In that curious way that waves have of sign reversal , it reflects and travels from whence it came, as a pressure wave , where we hope it will arrive just in time for the next rev cycle , so in that single crank revoluton the wave will travel once up and once back through the duct , so far so good .

Again , as with the ex , the wave will propagate at the local speed of sound and that is also temperature dependent . The numbers i have used here i took from some notes i made a while ago and they appealed as they work out to nice , easy to recognise , whole , values and visual clarity is always an advantage . It is no problem to substitute your own personal numbers which relate to your engine .

The air standard for speed of sound at 20*c is 343 m/s . As it is 4* as i type this , we will go for 300 m/s , and imagine that our engine is whacking round at 12,000 rpm, so that 1 rev takes .005 secs , therefore our wave travels .005x300 = 1.5 mtrs , then the duct length will have to be .75mtr , numerically correct , but just silly !

Let us now assume that the real duct length is 125mm , or .125mtr , divide the actual duct length into the theoretical one of .75mtr and we get 6 , meaning that the wave must travel a total of 12 times , 6 from the case and 6 from the bellmouth , to complete it`s journey .

There is a further complication in that the mean reflection point at the carb bellmouth is in fact beyond the bellmouth face , by around .5d of the carb in use , and, the bellmouth profile also has a measurable influence . The real problem with all of this back and forth business is that at every point in wave flow , energy is being lost and after a dozen trips the wave has little energy left to give ! Acoustic waves are themselves pressure waves and all the trips over the carb mainjet and float bowl are giving repeated , spurious signals which help to further mess up clean fuelling ! If after doing your own sums you end up with part of a wave ( ie 5.5 or 6.73 ) then you`ll have to get the big box of spacers out and fiddle around , the best advice maybe to start with a short duct initially and plan to adjust with 5mm spacers untill the sweet spot is found , then you can adjust else where , and do the whole thing all over again ! It would seem then that trying to calculate duct length by utilising wave travel is pretty pointless . But then there is always mass transport of mixture its self and all of the variables that could imply, like density , velocity , temperature .................???

Who said two strokes were simple ?

Regards to you all Trevor

| |

|   | | Sponsored content

|  Subject: Re: And quiet flows the duct ! Subject: Re: And quiet flows the duct !  | |

| |

|   | | | | And quiet flows the duct ! |  |

|

Similar topics |  |

|

| | Permissions in this forum: | You cannot reply to topics in this forum

| |

| |

| |